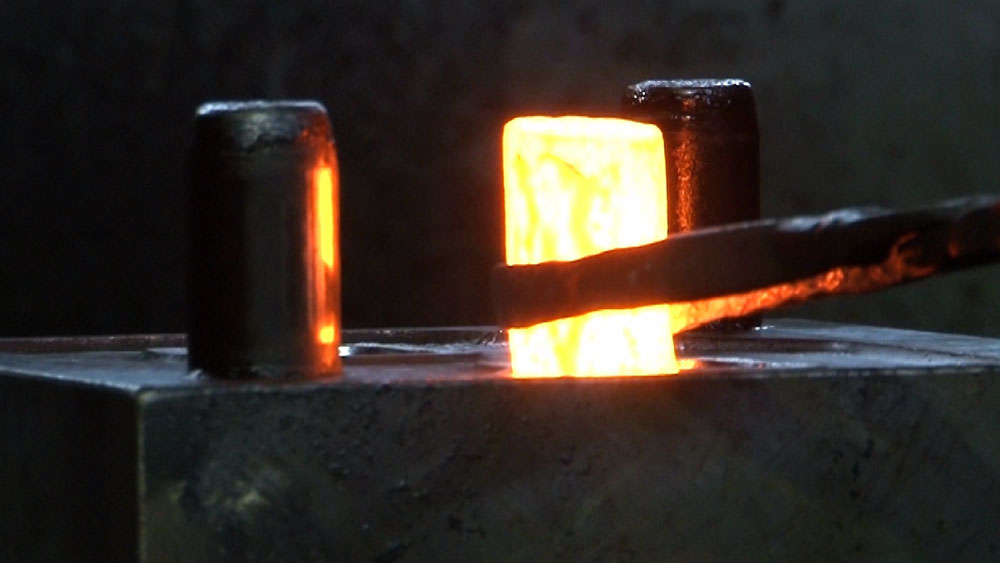

Forgings: Closed Die Processes

Forgings: Closed Die Processes introduces learners to the pre-forging processes, conventional forging, and final inspection. Ready to take the next step? Explore the course details and see everything we’ve packed into this program!

Learning Hours: 2

Representative or member of a corporation, educational institution, or trade organization? Contact us to discuss special pricing and additional benefits, including course activity reports for your group.