Workplace accidents, fatal and tragic, make headlines and fade away from our collective consciousness after their shelf-life in the news cycle; the less-grievous ones rarely gain media attention, nevertheless, they are commonplace. The Occupational Safety and Health Administration (OSHA) defines workplace accidents as, “an unplanned event that results in personal injury or property damage.” Industrial disasters are workplace accidents that involve multiple fatalities and leave a negative imprint on society—environmentally and epidemiologically—in its aftermath. The common thread connecting these workplace accidents and industrial disasters: freak incidents that often stem from overlooking safety protocols.

In the manufacturing sector, the risk of workplace accidents is relatively high in foundries. According to a report published by the United States Bureau of Labor Statistics (BLS) in 2019, the incidence rate of nonfatal injuries is 6.4 for every one-hundred full-time foundry workers; in this cohort, the incidence rate is 9.7% in steel foundries—the highest for metal casting foundries. A foundry environment presents with multiple hazards on the worksite: physical, chemical, electrical, and mechanical. Workplace accidents in foundries cause illnesses, injuries, and sometimes fatalities. Other implications of workplace accidents are job restrictions and lost production time. This post covers some of the cardinal rules of foundry safety.

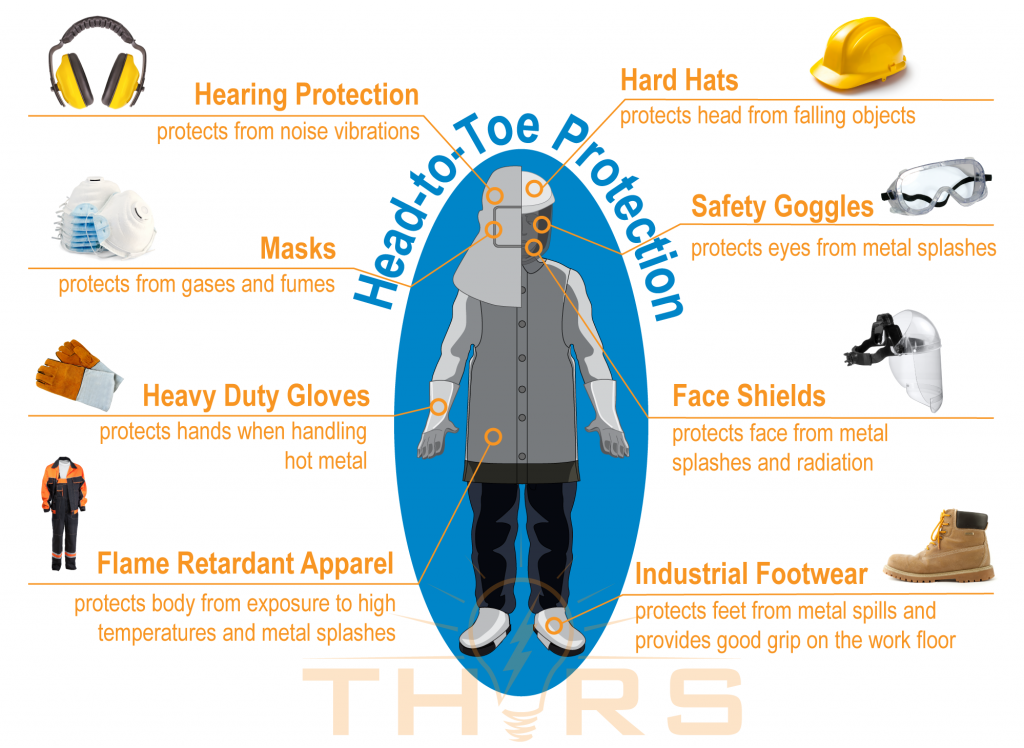

I. Wear Your Gear

Personal protective equipment (PPE) are designed to minimize the risk of exposure to workplace hazards. These protective gear come in various forms and offer head-to-toe protection. Knowledge of selection and maintenance of PPE is essential to reap its benefits.

II. Breathe Safely

The trio of adversaries—dust, fumes, and gases—are responsible for occupational respiratory disorders. Sand casting and fettling, or cleaning room operations, are major contributors of dust in the foundry. Prolonged exposure to dust in sand casting foundries can cause silicosis. Furnaces emit fumes and gases as a byproduct of melting operations. Properly installed dust collection systems and ventilation systems are the first line of defense for respiratory safety. Foundry personnel may be required to wear a mask or specialized respirators approved by the National Institute for Occupational Health and Safety (NOISH) as prescribed by their employers. To maximize protection, masks and respirators must be worn after a fitting test.

III. Inspect Before Use

Timely inspection of foundry machinery is critical for worker safety. Any defect or failure in equipment during a melt or pour can be extremely dangerous. Prior to use, operators must check the condition of equipment, furnace walls, fuel lines, burners, and pouring equipment.

IV. Know Your Melt

Foundry personnel should familiarize themselves with the chemicals and metals being handled. The common chemicals include abrasive cleaning chemicals, alloying elements, binders, and resins. Chemical storage containers are generally labeled in accordance with the OSHA Hazard Communication Standard Pictogram, and operators must always read labels prior to handling the chemicals. Operators must have a copy of the chemical Safety Data Sheets (SDS) for reference.

V. Keep Out Moisture

Moisture and molten metal are a lethal combination. Wet charge material is the leading cause of furnace explosion in foundries. Upon contact with the molten metal, moisture in the charge material changes to steam and expands up to 1600 times, causing explosions. Operators must ensure that the raw materials and tools are free of moisture.

VI. Adopt Good Housekeeping Practices

Good housekeeping practices are crucial for preventing workplace injuries resulting from trips and falls. Operators must diligently follow all housekeeping rules and keep the foundry floor clear of wires and other trip hazards.

VII. Be Vigilant

Vigilance is vital in detecting accidents early on and helps in preventing serious damage to personnel and property. Foundry personnel must always be wary of their surroundings. Coworkers and supervisors must be alerted if something is suspicious. For example, uncommon odor could indicate a gas leak or a metal leak.

VIII. Administer First Aid

Accidents happen despite the best planning, precautions, and care. Personnel must be equipped to access and administer basic first aid before help arrives. All personnel must know the locations of showers, water stations, fire extinguishers, emergency access doors, and phones situated in the facility. Personnel must follow protocol for reporting injury to a supervisor to avoid chaotic communication.

IX. Follow Communicable Disease Plan

Emerging viral infections pose a safety hazard in all workplaces. Be informed of the company’s injury and illness protection program safety plan. The plan contains guidelines for the responsibilities of all the stakeholders, incident reporting protocols, assessment methods, and corrective measures to be implemented. Employees must follow the public health measures in place.

X. Train to Foster Safety

Safety is a priority and a responsibility of all. Effective communication and timely training practices ensure the good health and safety of all employees. Foundry personnel must be trained on their company’s evacuation plan and emergency response plans. These plans must focus on specific situations, such as measures to contain a spill due to flask failure, a cracked crucible, or a failure in the pouring hardware.

Final Thoughts

Workplace accidents are often a product of negligence and unsafe practices. As Benjamin Franklin once said, “An ounce of prevention is worth a pound of cure,” investing in training solutions that equip employees to proactively follow safety practices and identify possible hazards is the best strategy for risk mitigation.

Fulfilling the first nine commandments rests on the final commandment—training. Safety training is often bland and boring. THORS eLearning Solutions has been a gamechanger in industrial safety training; our courses are content rich, highly engaging, and visually stunning. Our custom courses team will work with you to customize your training program. Our assessment tool can be tailored to meet your compliance needs. Experience the power of our training solutions that promote a “safety first” workplace culture.

Get in touch with our team: sales@thors.com.