To ensure workplace safety, it is crucial to follow safety directives for handling grinding wheels. Grinding wheels are used to remove excess material from metal workpieces, achieving dimensional accuracy and a fine finish in various precision grinding operations. When it comes to industrial work, safety should always be the top priority. This is especially true when it comes to the use of grinding wheels, which can pose significant safety risks if not handled properly.

As Kina Repp, a workplace accident survivor and motivational speaker, reminds us, “You are your last line of defense in safety. It all boils down to you.” To maintain a safe and productive workplace, it is essential for workers and their teams to prioritize safety when handling grinding wheels. This includes following comprehensive safety directives to minimize the risk of accidents and injuries.

1. Inspect and Test the Wheel

Check the wheels received from the manufacturer for any potential damage, and always store the wheels in a dry area. Do not roll the wheel on the ground. Vitrified grinding wheels, made by fusing grains of abrasive materials with a glass-like bond, should always undergo a ring test before mounting to ensure they are defect-free and safe to use. A damaged wheel will sound dull; a crack-free vitrified wheel would sound clear and bell-like. Do not use the wheel if a dull sound is heard.

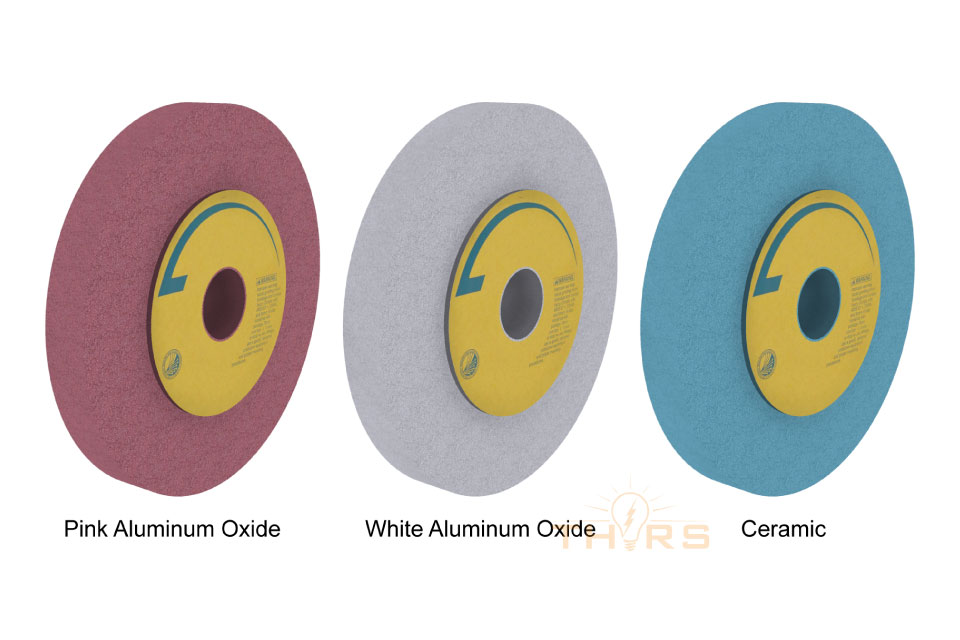

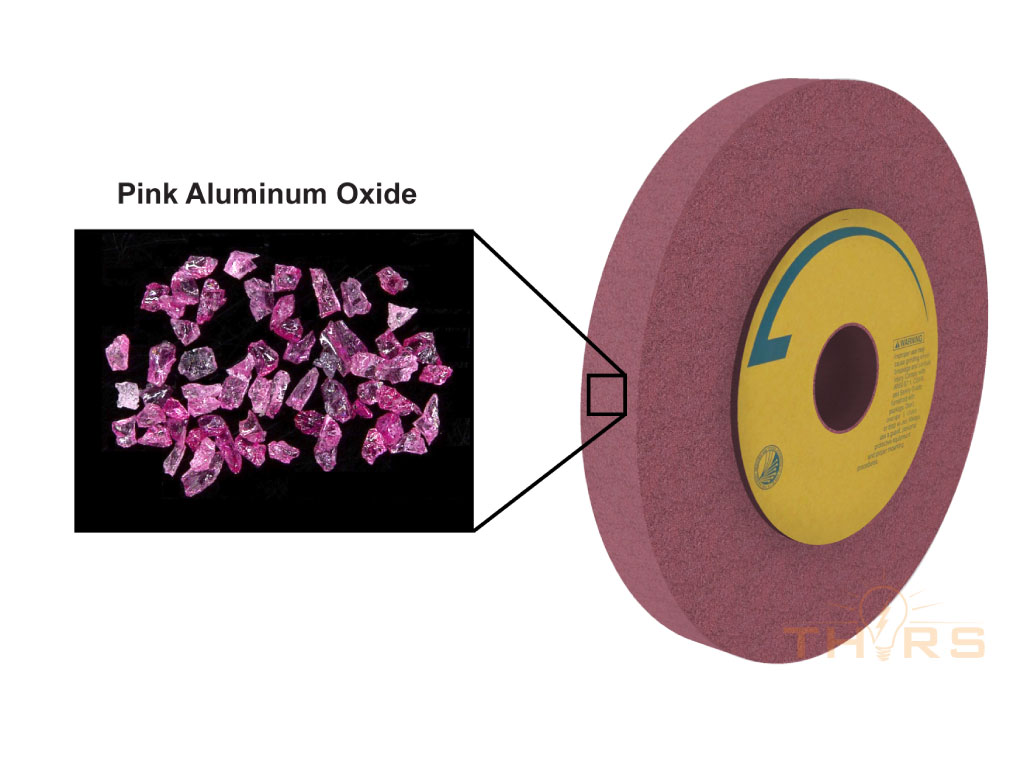

2. Select the Grinding Wheel Appropriately

Select the appropriate grinding wheel for a specific workpiece material to ensure the safety and quality of the grinding process. Using a grinding wheel that is not suitable for the material being ground can result in a poor surface finish, slow material removal, and even wheel breakage.

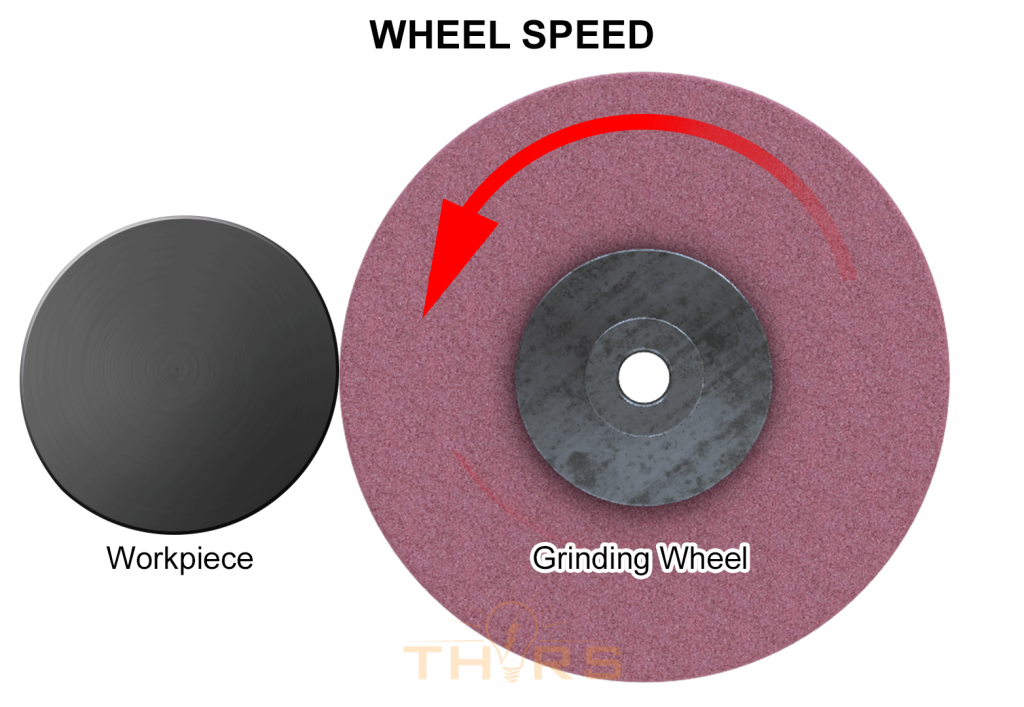

3. Match the Grinding Wheel Speed and Machine Speed

Ensure that the operating speed of the machine does not exceed the maximum allowable speed marked on the grinding wheel. This is because exceeding the maximum allowable speed can lead to accidents, such as wheel breakage or disintegration, which can cause injury to the operator and damage to the machine.

4. Obey the Speed Limit

Do not operate the grinding wheel at a surface speed greater than that specified on the wheel. Additionally, newly mounted wheels should be run at operational speed for at least a minute to check for any balance issues or defects and to warm up the wheel to prevent thermal cracking.

5. Never Use Excessive Force to Mount Grinding Wheels

Never try to push a grinding wheel onto a machine if it does not fit. When a grinding wheel is forced onto a machine, it can cause stress on the wheel and result in cracks or breaks. Moreover, avoid enlarging the mounting hole to fit the grinding wheel, as it can lead to unstable mounting and cause vibrations during the grinding process.

6. Avoid Overtightening of Nuts and Screws

Do not overtighten the nuts and screws used for mounting the wheel. Overtightening can cause the wheel to become deformed and lead to an imbalance, which can cause the wheel to break during operation, leading to serious injuries.

7. Stop Coolant First, Wheel Next

Do not stop the wheel until the coolant supply has been cut off. If the wheel is stopped while the coolant is still being supplied, the coolant can be forced into the wheel’s pores, causing the wheel to become saturated and reducing its effectiveness.

8. Say "Yes" to PPE

Always wear appropriate Personal Protective Equipment (PPE), such as a face shield, safety goggles, and hearing protection when operating a grinding wheel. Additionally, it is essential to wear close-fitting clothing to prevent any loose items such as ties and shirt sleeves from getting caught in the machine’s moving parts. Failure to wear proper PPE can result in serious injury or even death, so safety should always be a top priority when using a grinding wheel.

9. Dress the Wheel

Dress the wheel whenever required for efficient grinding. Dressing is the process of restoring the cutting ability of a grinding wheel by removing the dulled abrasive grains on the wheel surface to improve its performance and extend its lifespan. An undressed wheel can compromise the surface finish of the workpiece being ground, generate excess heat, and increase the risk of workplace injuries. Additionally, debris accumulated on the wheel can cause it to become unbalanced, leading to vibrations and potential breakage.

10. No Side Grinding Unless Specified

Understand the specific grinding wheel’s design and purpose to ensure safe and effective use. Using a grinding wheel for a purpose other than its intended use or applying excessive pressure on the side of the wheel can cause it to shatter and fly apart, sending debris flying at high speed, posing a significant risk to the operator and others in the vicinity.

If you are looking to enhance your understanding of abrasive grinding wheel safety and prevent accidents in the workplace, our THORS course on “Precision Grinding: Abrasive Wheel Safety” provides valuable insights and practical tips to help you promote a safe working environment.