Course Description

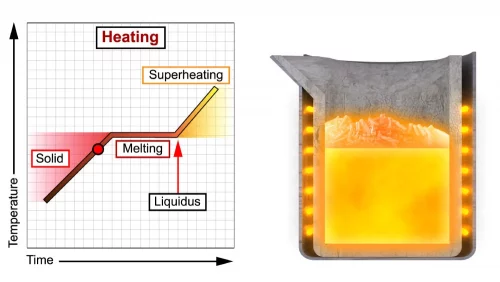

Iron Melting Fundamentals is an introduction to iron casting processes, including the raw materials, charge preparation, and melting equipment used in modern foundries. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment and terminology associated with their profession.

Who will benefit from this Iron Melting course?

Companies, individuals, or educational institutions that produce or require an understanding of cast iron.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Iron Melting Fundamentals

*upon successful completion

Related Posts

A Differentiated Learning Approach: A Closer Look at THORS

In the wide landscape of learning methodologies, the pursuit of engaging and effective learning approaches has been ongoing. Among the myriad approaches, a differentiated learning

What are Bonded Sand Aluminum Casting Molds and Common Defects?

What is bonded sand aluminum casting? Bonded sand aluminum casting involves heating aluminum to molten temperatures and pouring it into molds of a specific size,

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The