Course Description

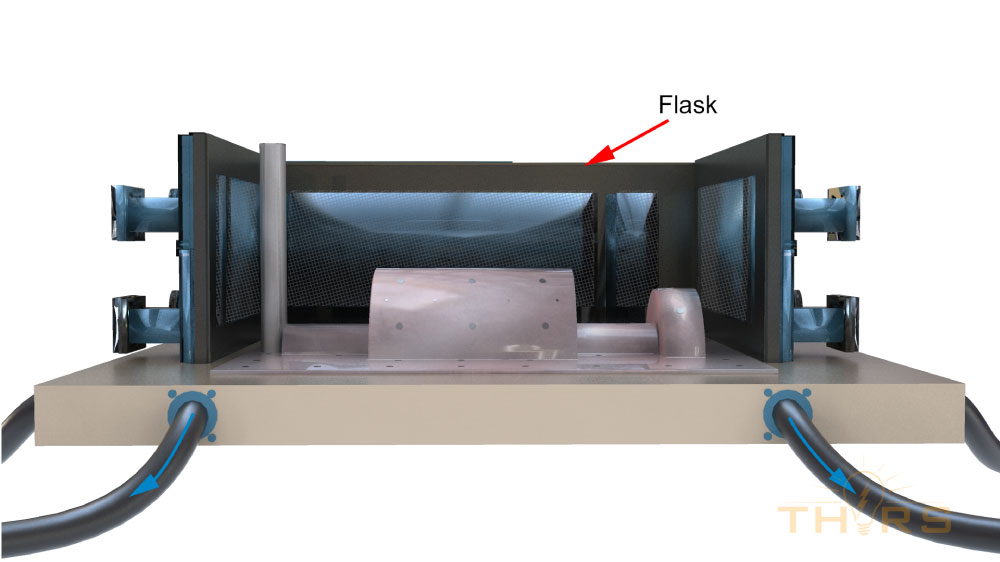

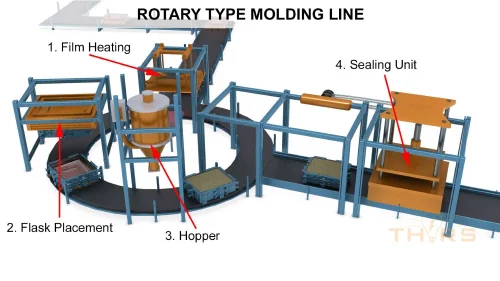

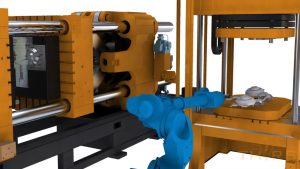

Vacuum Process Fundamentals introduces the learner to casting production by Vacuum Process Molding. The course provides an overview of the common defects and troubleshooting guidelines. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment processing steps associated with their profession.

Who will benefit from this Vacuum Process course?

Companies, individuals, or educational institutions that require an understanding of the equipment, processes, and post-processes involved in producing castings by vacuum process molding.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Vacuum Process Fundamentals

*upon successful completion

Related Posts

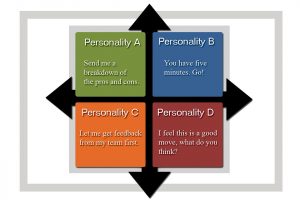

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also