What is bonded sand aluminum casting?

Bonded sand aluminum casting involves heating aluminum to molten temperatures and pouring it into molds of a specific size, shape, material, and design. Bonded sand molds are commonly used to complete the process, accounting for roughly 60% of aluminum castings worldwide. It is important to understand the basic parts of bonded sand molds and the common defects associated with the casting process.

What are the basic parts of bonded sand aluminum casting molds?

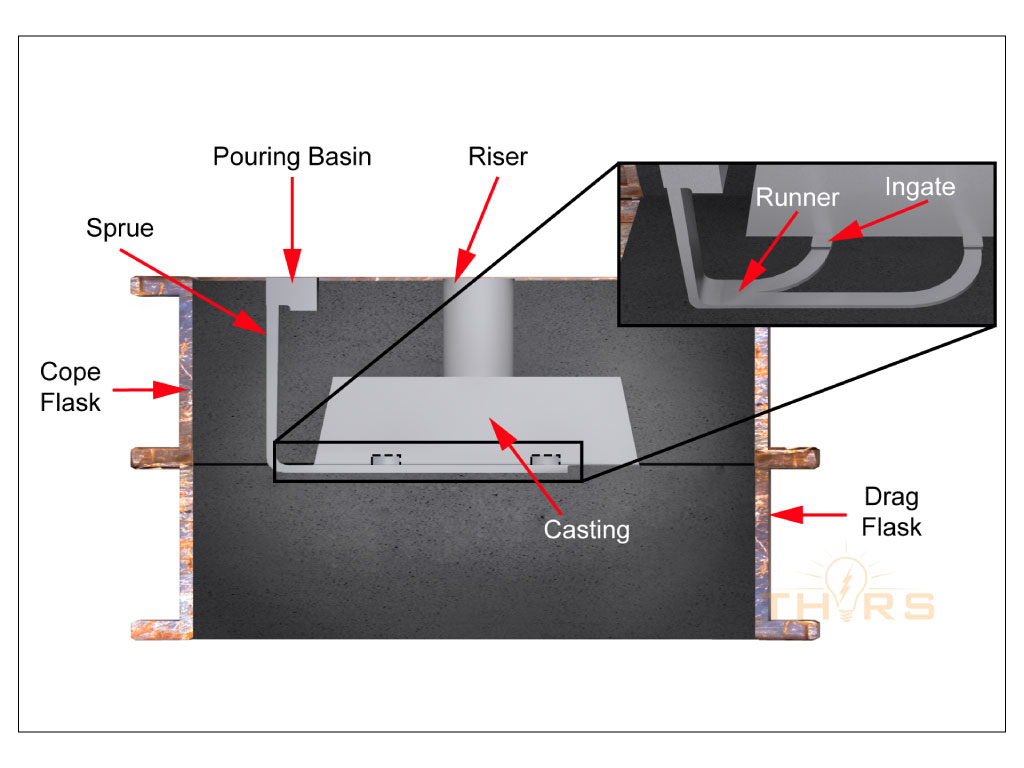

This example is a simple representation of the basic parts of a bonded sand aluminum casting mold.

- The pouring basin is the location where the molten metal is poured and enters the filling system.

- The sprue, or downsprue, guides the molten metal into the mold.

- A runner is typically a long and thin channel that distributes metal around or under the casting.

- An ingate, also referred to as a gate, is a channel leading from the runner into the casting.

- A casting is the part being created. All the features in the filling system are designed to facilitate the proper entrance, filling, and solidification of metal in the casting cavity.

- A riser, or feeder, is a reservoir of liquid metal that compensates for the shrinkage that occurs when metal solidifies.

- The parting line is the plane where the two mold halves meet.

- The cope flask is the top half of the mold.

- The drag flask is the bottom half of the mold.

- Sand is the primary mold material.

What are some common defects for bonded sand aluminum casting?

Here are some examples of common defects for bonded sand aluminum casting:

- Shrinkage porosity occurs when metal is solidifying and contracting, but there is not sufficient liquid metal to feed the void in the casting.

- Gas porosity occurs when gases attempt to escape the solidifying metal and form voids within the casting. Pinholes are another form of porosity that appears on the open surface of castings.

- Defects such as rough surface, metal penetration, and burnt-on sand may result from the molten metal penetrating into the sand of cores and molds.

- Sand inclusions consist of sand from the mold or cores that have broken away, or loose sand in the cavities not blown away during mold closing.

- Slag inclusions occur when melting and processing residue ends up in the casting.

- Veins are thin projections of metal on the surface of castings, especially on the cored surfaces.

- Fins are thin pieces of metal that form if there is a gap in-between the mold halves.

- Mismatch defects are related to shifting or incorrect placement of the mold halves and cores.

To learn more, try our THORS course Bonded Sand Aluminum Casting Basics course which introduces the learner to the world of aluminum alloys and bonded sand molding, including the properties, processes, and terminology associated with aluminum casting production.