Course Description

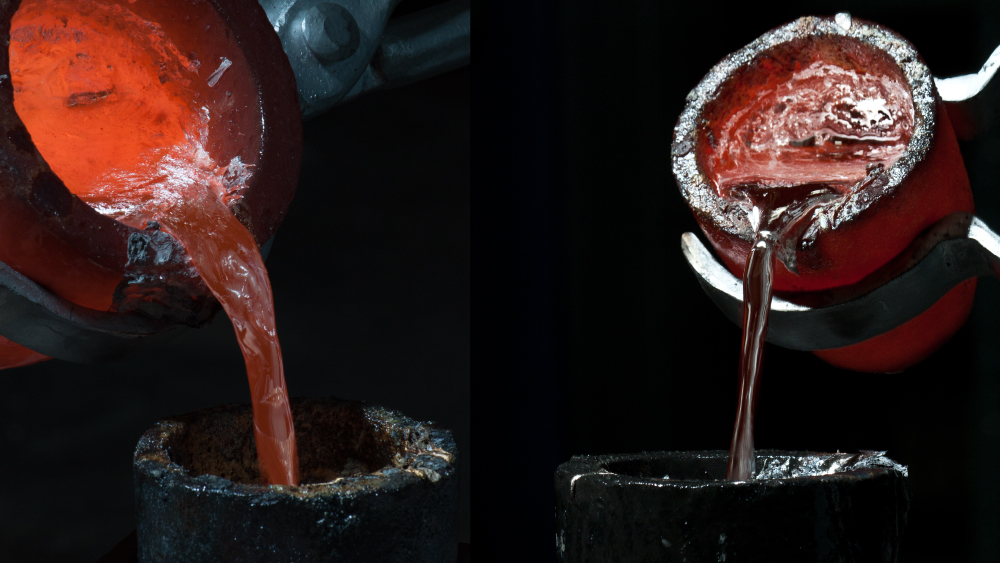

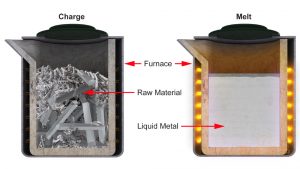

Aluminum Melting Fundamentals examines the equipment, processes, and general terminology associated with aluminum melting and casting foundries. Presented in THORS’ highly visual and interactive format, this course provides learners with a variety of important topics for this expanding industry. From learners who are new to aluminum casting industries, to seasoned veterans, there is relevant knowledge for everyone in this course.

Who will benefit from this Aluminum Melting course?

Companies, individuals, or educational institutions that are required to properly melt, modify, and pour aluminum castings.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Aluminum Melting Fundamentals

*upon successful completion

Related Posts

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also

Manufacturing Sustainability in Metal Casting Industries

Metal casting is the manufacturing process of pouring molten metal into a mold to create a required shape. While metal casting has been an important

Must-read Monday: A mini-guide to basic foundry concepts

Every now and then we need to brush up on our knowledge. Let’s revisit some of our popular blog posts which are aimed to help