Have you ever driven a vehicle down the road and thought, how does this steering system work? Nowadays, we drive the most sophisticated, nearly flawless automobiles without giving much thought to the amount of engineering that has gone into them. A steering system is no exception to the genius that contributed to improving the components of the steering system, making them more beneficial to drivers.

What are the Major Components of a Steering System?

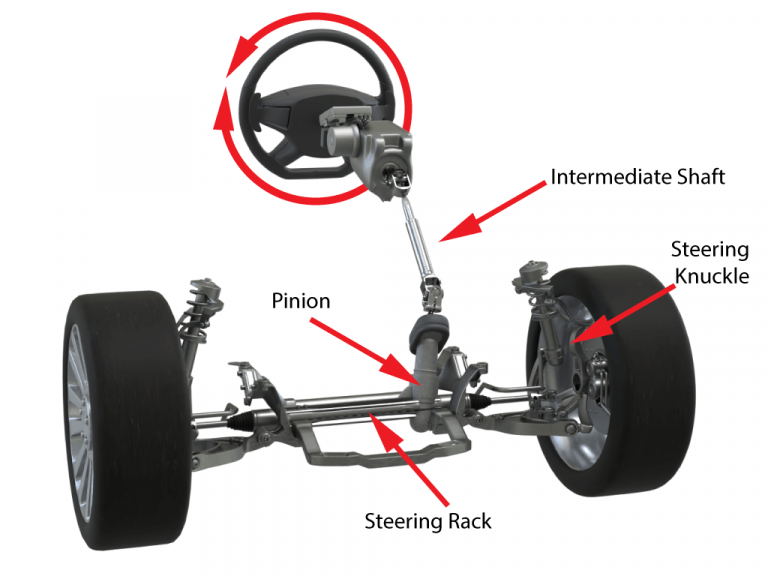

Many components of the steering system require smooth interactions with one another to ensure safety and reliability. The steering wheel is the contact point where the driver physically holds onto and rotates when a turn is required. As the steering wheel is turned, an intermediate shaft rotates. At the end of the intermediate shaft is an input shaft. The input shaft is directly connected to the pinion.

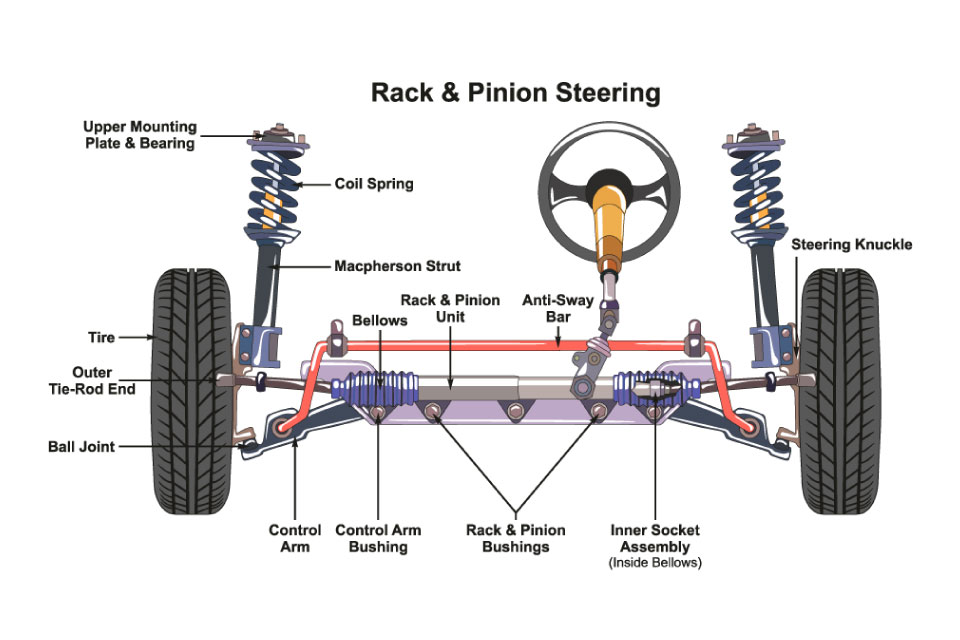

The pinion is the smaller gear that meshes with the teeth on the steering rack. Whatever way the driver decides to turn, the pinion rotates in that direction and pushes or pulls the steering rack left or right. At the end of each steering rack are tie rods. The tie rods are inner and outer tie rods that transfer force to the steering knuckles. The steering knuckles connect the suspension system and steering system to the wheel end assembly, acting as the final component before the tires are turned.

What is a Rack and Pinion?

WHAT IS A RACK AND PINION?

The most common type of steering system is a rack and pinion style system. The rack and pinion design was used for nearly 100 years in railroad applications before being implemented into Internal Combustion Engine (ICE) vehicles and Electric Vehicles (EV). The rack and pinion are the combination of two components directly responsible for taking rotational motion from the pinion and translating it into linear motion that is necessary to turn a vehicle’s wheels. Although the rack and pinion steering system is good for turning vehicles, a disadvantage of the system is the amount of friction to overcome, requiring physical strength to turn the tires of the vehicle. In order to improve the drivability of a vehicle, engineers developed brilliant designs to use powered components to reduce the required energy.

When was the Power Steering System Implemented into a Vehicle?

In the past, drivers relied on physical energy to turn the entire vehicle. Turning a vehicle with an average weight of 1814 kg (4,000 lbs.) using physical energy was no easy feat. Power steering is the reason drivers are able to turn a vehicle with ease, in the direction that they want it to go. Sometime in the 1950s, engineers had the brilliant idea of adding a hydraulic system that would assist the driver when turning the vehicle’s wheel. Fast forward a couple of decades and the Electric Power Steering (EPS) system was developed to enhance the driving experience by reducing driver fatigue.

Why are Future Steering Systems Electric?

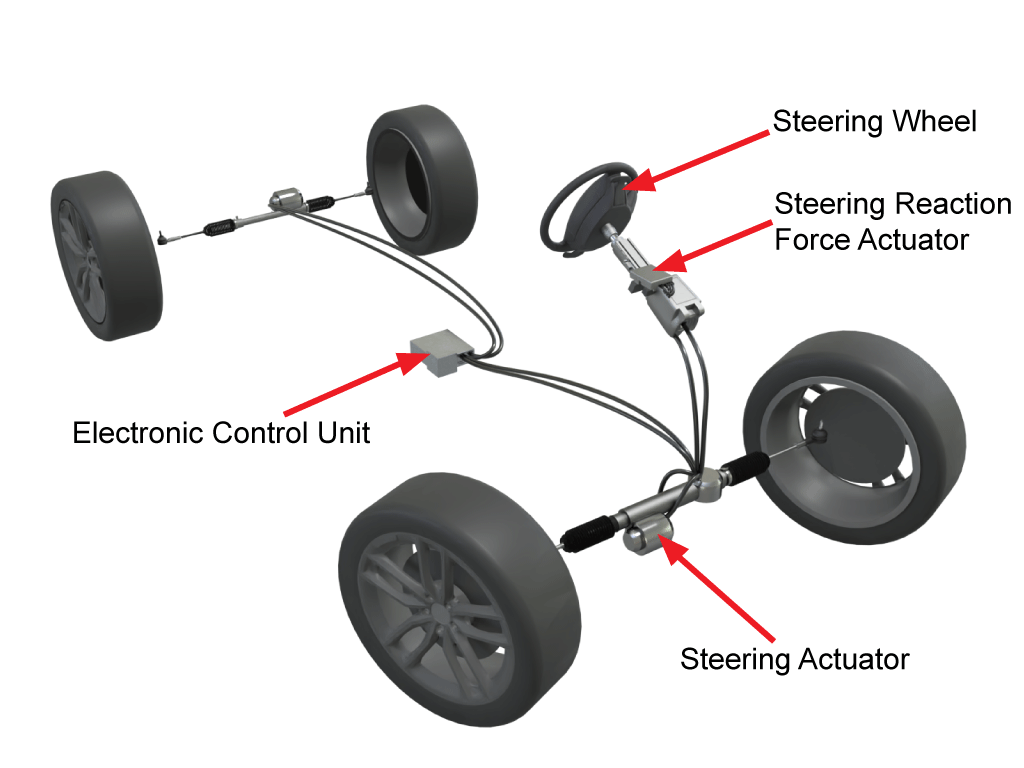

Advancements in electric steering began in the aerospace industry. Airplanes rely on a technology called fly-by-sire where all mechanical connections have been replaced by electronic devices. This is a very safe and reliable way to steer a vehicle; so naturally, the automotive industry started developing a steer-by-wire system that replaces the mechanical connection between the steering wheel and the steering system with electrical components. There are many redundancies added to the steer-by-wire system to ensure that failure of the steering system doesn’t occur.

In conclusion, the evolution of the steering system is a remarkable example of how continuous innovation in engineering can significantly enhance our driving experience. From the basic mechanics of rack and pinion to the advanced technologies of power steering and steer-by-wire systems, each development has made driving safer, more efficient, and more enjoyable. As we look to the future, it’s clear that electric steering systems, inspired by aerospace technology, will continue to revolutionize how we interact with our vehicles, offering even greater precision and reliability.

If you’re fascinated by the intricate engineering behind steering systems and want to learn more about the technologies shaping the future of automotive design, we invite you to explore our comprehensive range of courses at THORS.com. Dive deep into the world of automotive engineering and discover the cutting-edge innovations that are driving the industry forward. Join us on a journey of discovery and be part of the next wave of automotive excellence.

Embark on your automotive learning adventure today with Steering Basics – where engineering meets innovation.