What is the lithium-ion battery manufacturing process?

Lithium-ion battery manufacturing is the method of producing lithium-ion batteries that employ lithium ions as their main source of energy. The manufacturing process entails several steps, including the manufacture of the anode, cathode, electrolyte, and separator, followed by the assembly of these components into a complete cell. The cells are put through formation and testing after assembly to make sure they satisfy specific performance standards.

Lithium-Ion Batteries (LIBs) have integrated themselves into every aspect of our daily lives since they can power everything from our smartphones to electric cars. The high-energy density, good cycle life, and low self-discharge rate of these batteries account for their widespread use. The extensive use of lithium-ion batteries in portable gadgets, electric vehicles, and renewable energy storage systems makes it a significant industry. The prevalent question is, though, how are these batteries made?

What are the 10 steps in the manufacturing of lithium-ion batteries?

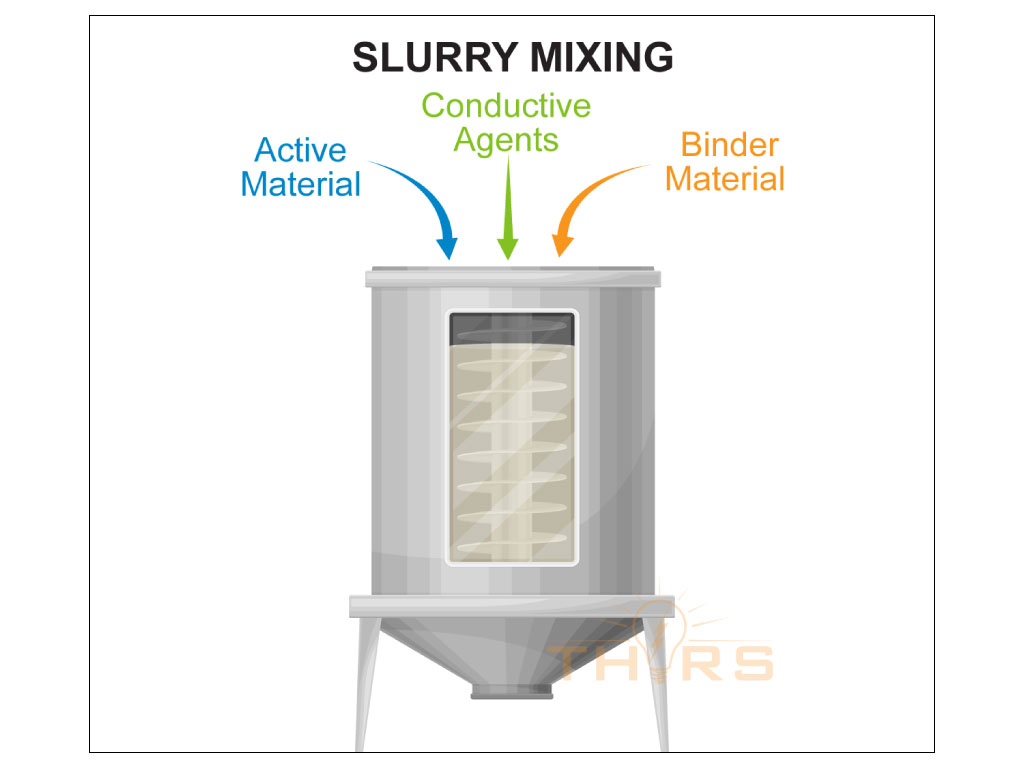

1. Slurry Mixing

The first step in lithium-ion battery manufacturing is to prepare the electrode slurry. The respective active material for the anode and the cathode is mixed with a binder and a conductive additive to form a slurry with the solvent.

2. Coating

The prepared slurry is coated onto the corresponding metal foil for the anode and the cathode.

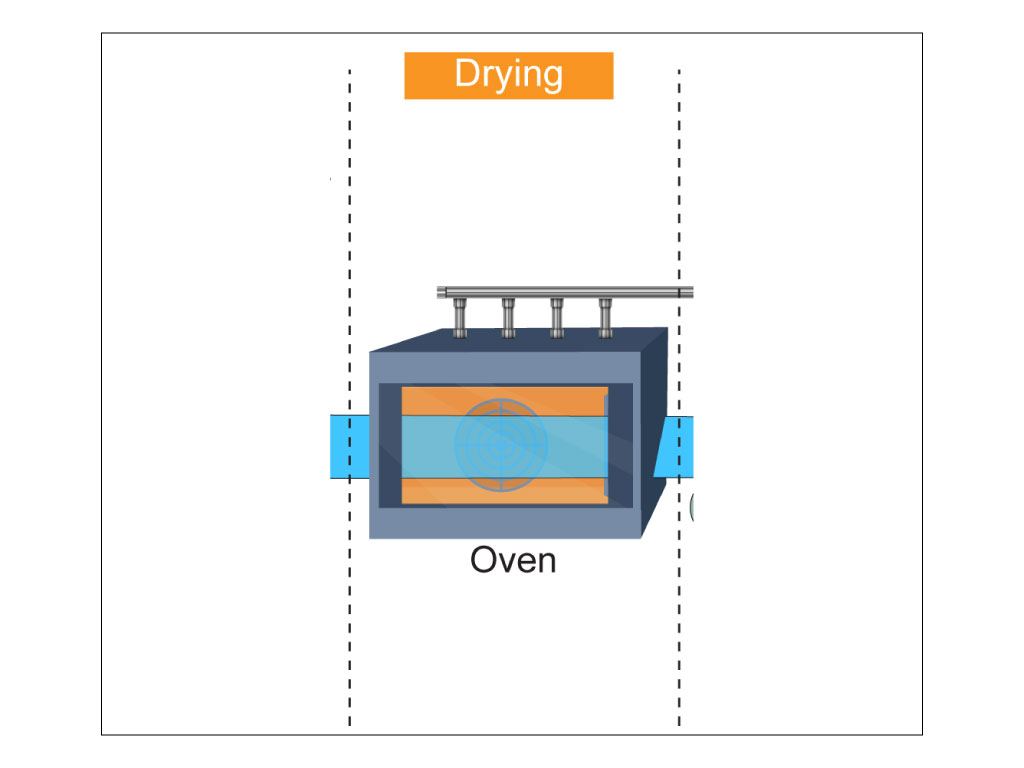

3. Drying

Drying removes excess moisture from the metal foils using drying equipment.

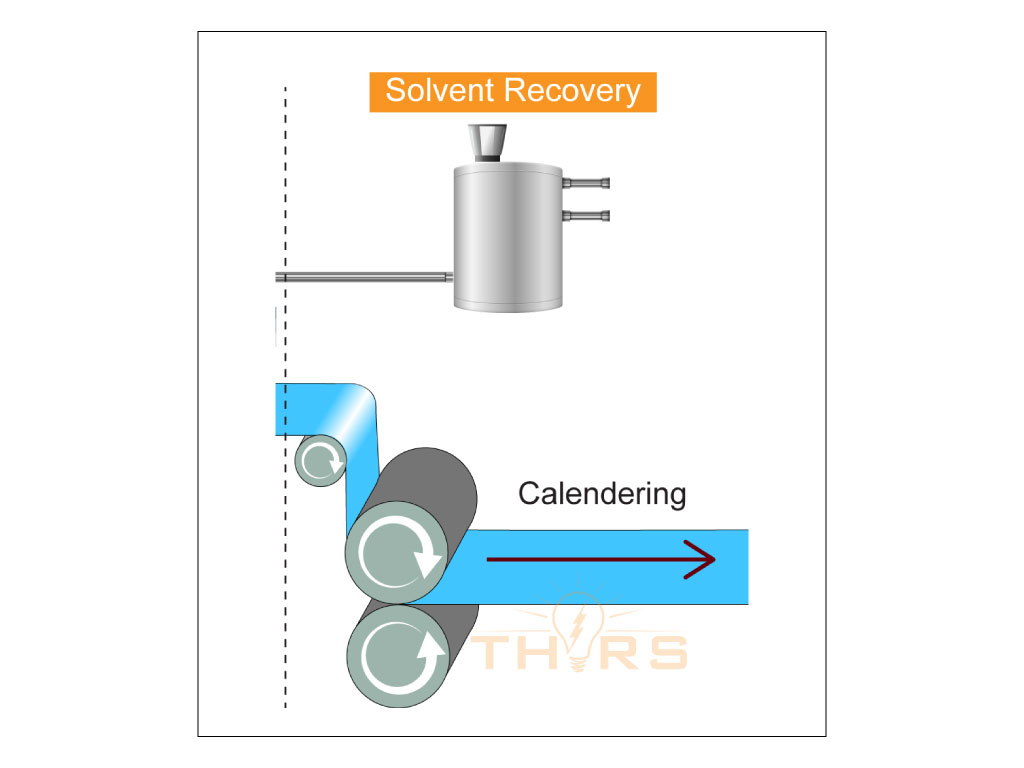

4. Solvent Recovery

Solvent recovery is the process of extracting the harmful and toxic solvent used for preparing the cathode slurry.

5. Calendering

The calendering process involves compacting the electrode foils by passing them through a pair of cylindrical rollers.

6. Slitting

Slitting is the process of cutting the electrode foil into the required dimensions.

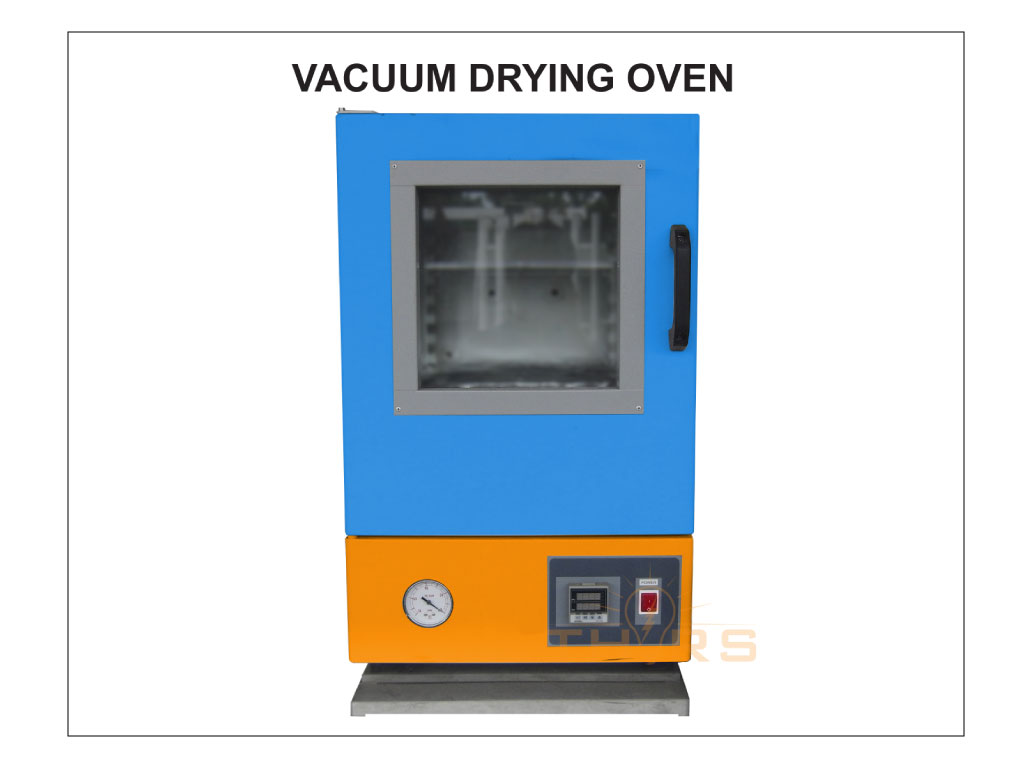

7. Vacuum Drying

Vacuum drying is the process of removing residual moisture from the electrodes using a vacuum oven.

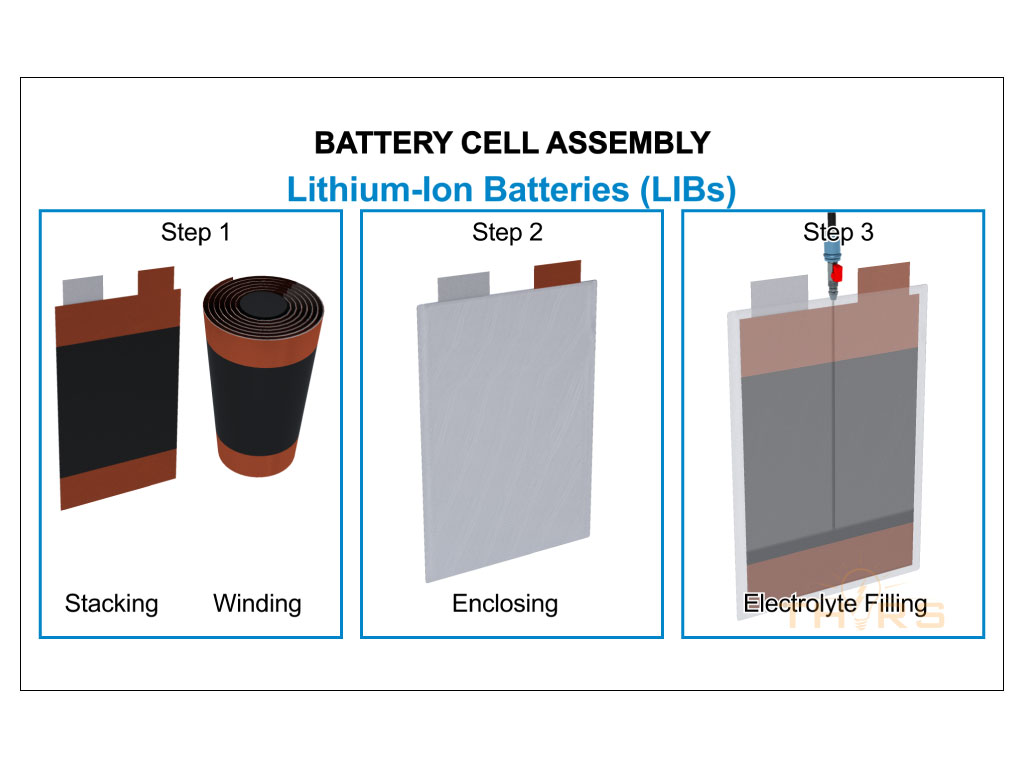

8. Cell Assembly

Cell assembly is the process of assembling the battery cell, placing it in an enclosure, and filling it with the electrolyte.

9. Forming

Forming is an electrochemical activation step that results in the formation of a Solid Electrolyte Interphase (SEI) on the anode of the battery during the initial charging and discharging cycles.

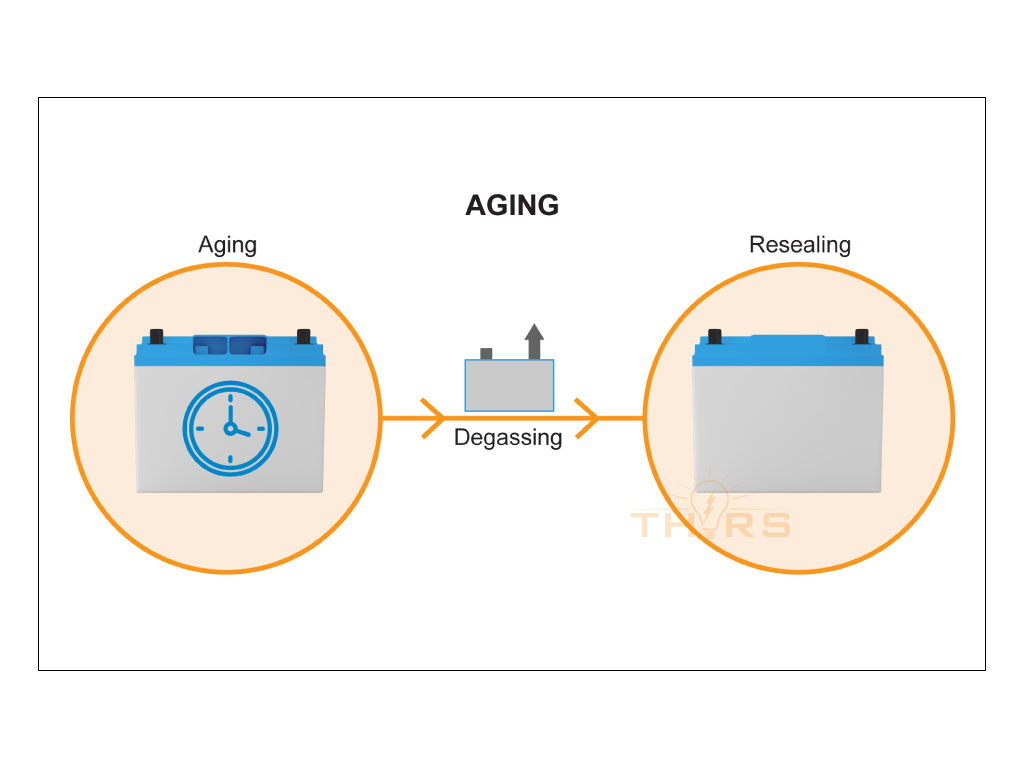

10. Aging

Aging is the final step where the cells are stored on the aging shelves to stabilize the SEI. Degassing is carried out at this step for safety reasons. The cells are tested to ensure they meet specific performance criteria, such as capacity, voltage, and cycle life.

What are the major challenges in lithium-ion battery manufacturing?

- Lithium-ion batteries have the risk of catching fire or exploding if they are not properly made. To protect the health of both workers and end users, safety precautions must be implemented.

- The cost of producing lithium-ion batteries is high and is influenced by several factors, including the quality of the raw materials utilized, the manufacturing method, and the volume of production.

- To ensure reliability and consistency, lithium-ion batteries need stringent quality control procedures. The performance and safe working of the battery may be impacted by any deviation from the manufacturing process that results in defects.

- Lithium-ion battery manufacturing involves the use of hazardous substances and materials that may be harmful to the environment. To reduce the environmental impact of battery production, manufacturers are always on the lookout for sustainable manufacturing techniques.

- It is difficult to get the raw materials required for producing lithium-ion batteries, and their costs are unstable. To prevent production delays and cost overruns, manufacturers must guarantee a consistent supply of raw materials and effectively manage their supply chains.

If you are interested in expanding your knowledge and gaining valuable insights into the lithium-ion battery manufacturing processes, our THORS course on Battery Manufacturing Processes is the perfect opportunity for you to take your understanding to the next level.