Course Description

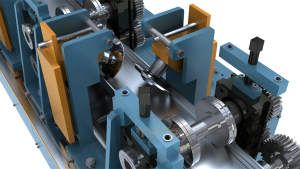

Metal Forming Process Selection is designed to provide learners with a better understanding of how to select metal forming processes based on part requirements and other important variables. This course provides learners with a greater understanding of the various processes utilized for forming sheet metal, the advantages and disadvantages of each process, and important factors such as part volume, material transportation, and packaging constraints.

Who will benefit from this Metal Forming Processes course?

Purchasers, Design Engineers, Manufacturing Engineers, and other related positions required to make informed decisions for the design, purchase, manufacture, and repair of parts formed with sheet metal.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Metal Forming Process Selection

*upon successful completion

Related Posts

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

How Can THORS Help Enhance Your College Education?

How Can THORS Help Enhance Your College Education? THORS Academy can help enhance your college education in a number of ways. Imagine being in a

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools