Course Description

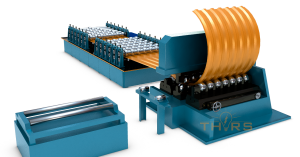

Roll forming is a metal forming process in which metal in the form of sheets, coil, or strips is converted into an engineered shape. The THORS Roll Forming Basics course is relevant for learners who are new to the industry, as well as experienced learners that require a deeper knowledge of the roll forming line equipment, the different machine configurations, the procedure involved in the designing the rolls, and a deeper insight into the roll forming process and secondary processes carried out in the roll forming line. In addition, the course explores major defects and troubleshooting techniques that occur on the formed product during the roll forming process.

Who will benefit from this Roll Forming course?

Sales, Quality, Engineering, Purchasing, and Manufacturing

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Roll Forming Basics

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry