Course Description

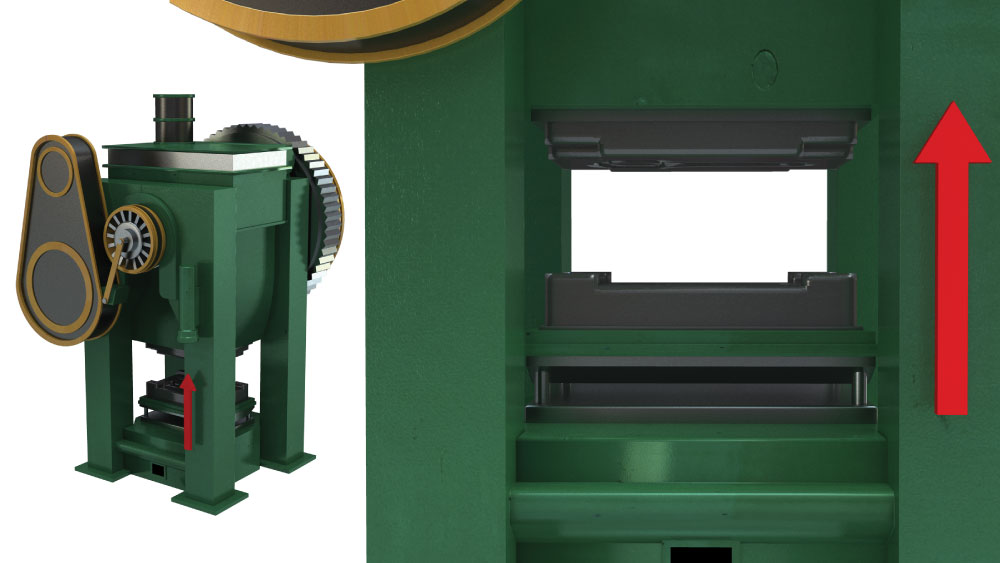

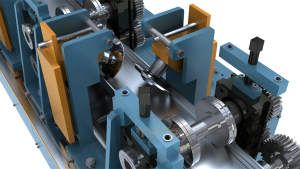

Forgings: Closed Die Terminology and Equipment introduces learners to the basic equipment, concepts, and general terminology that are often applied for closed die forging industries.

Who will benefit from this Closed Die Forging Terminology and Equipment course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that perform forging operations. Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Forgings: Closed Die Terminology and Equipment

*upon successful completion

Related Posts

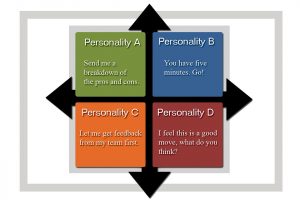

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has