Course Description

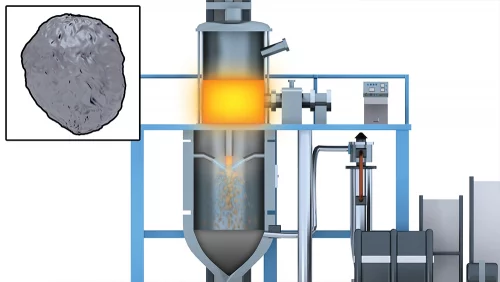

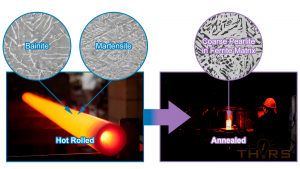

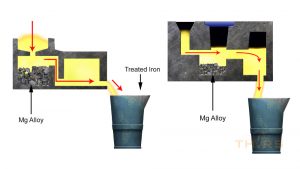

Powder metallurgy is an ancient technology that has made a resounding comeback and has enhanced modern engineering capabilities. The THORS course Powder Metallurgy Basics presents a comprehensive view of powder metallurgy technology. This introductory course, replete with audio, video, and interactive learning experiences, enables learners to discover powder processing and part processing methods. In addition, this course offers insights into the characterization of metal powders and its impact on the behavior of the bulk material.

Who will benefit from this Powder Metallurgy course?

Sales, Marketing, Business Development, Technicians, and Quality

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Powder Metallurgy Basics

*upon successful completion

Related Posts

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

Non-destructive testing: Creating a safer world

You will be surprised to know how much of our daily safety depends on non-destructive testing (NDT). In 2014, at least 126,698,000 lug nuts were