Course Description

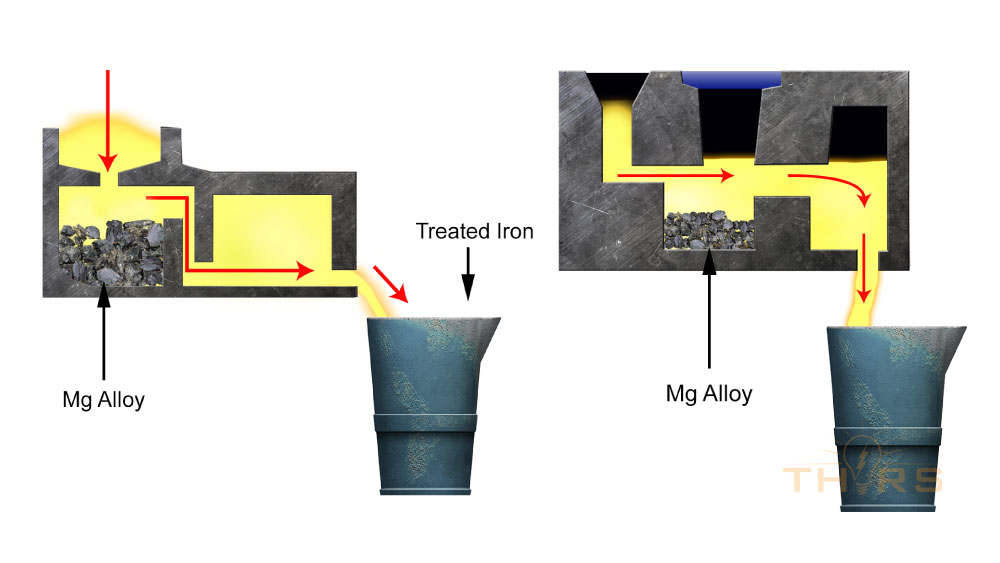

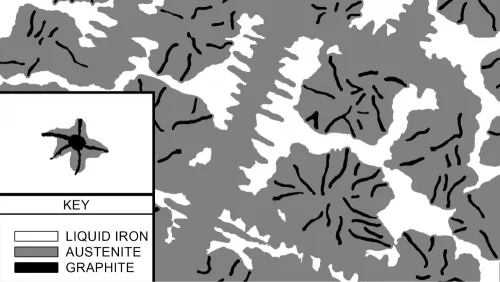

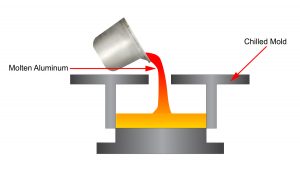

Ductile Iron Fundamentals introduces the learner to the properties, processes, and terminology associated with ductile iron production. This course also includes defect analysis of the manufactured product. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment processing steps associated with their profession.

Who will benefit from this Ductile Iron course?

Companies, individuals, or educational institutions that require an understanding of the terminology, properties, processes, and quality improvement procedures associated with ductile iron foundries.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Ductile Iron Fundamentals

*upon successful completion

Related Posts

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the