Course Description

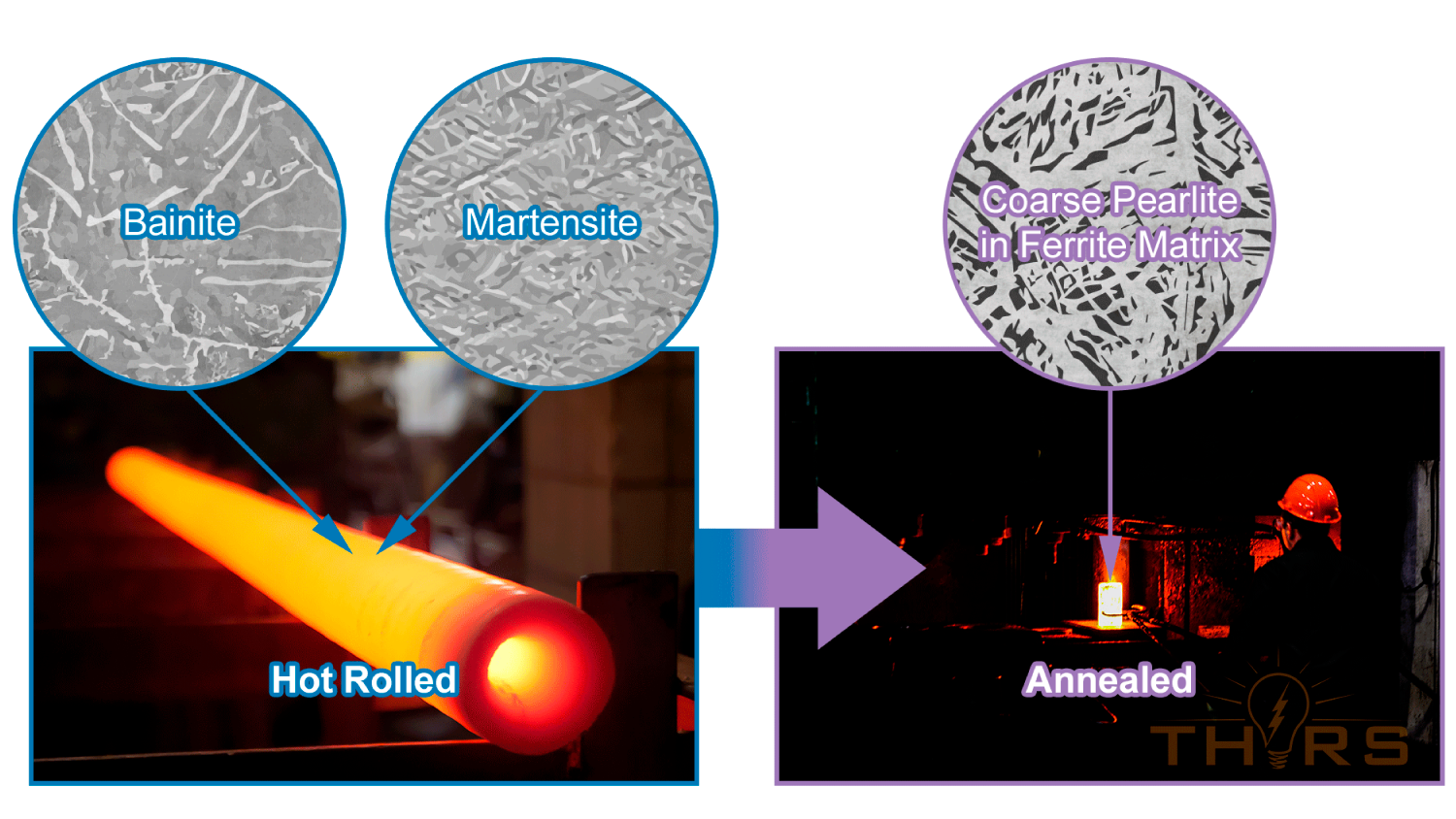

The THORS Steel Tubing Basics course explains the various primary and secondary specifications of steel tubes. The size and material specifications are discussed under the primary specifications of steel tubes. The various heat treat conditions are explained, along with the microstructural and chemical changes that happen at different stages of heat treatment. The secondary specifications, such as finished condition, corrosion resistance, and industry standards, are explored in detail. This introductory course offers an interactive learning experience that allows learners to gain an in-depth understanding of steel tubes.

Who will benefit from this steel tubing course?

Sales, Purchasing, Manufacturing Engineering, Quality, and Design Engineering

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Steel Tubing Basics

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Boosting Employee Engagement in eLearning

Introduction In the realm of modern workplaces, boosting employee engagement in eLearning has become a pivotal factor in fostering productivity, job satisfaction, and overall organizational

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.