Course Description

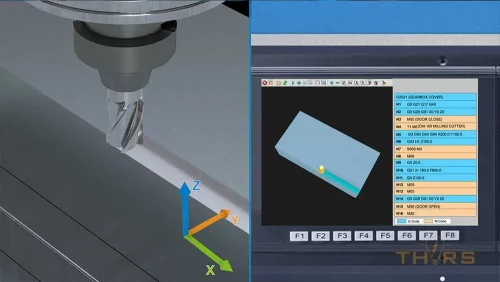

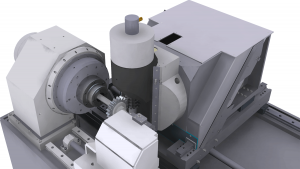

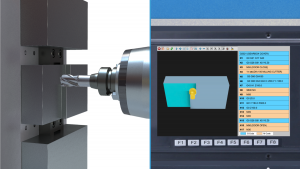

The Vertical Machining Center Video Series 2 introduces learners to concepts that are important to the vertical machining process, such as workholding methods, cutting parameters, tool offsets and setting, and basic program codes. Important safety, best practices, and troubleshooting techniques for vertical machining operators are also presented.

Who will benefit from this Vertical Machining Process video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Vertical Machining Center Video Series 2

*upon successful completion

Related Posts

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

A Differentiated Learning Approach: A Closer Look at THORS

In the wide landscape of learning methodologies, the pursuit of engaging and effective learning approaches has been ongoing. Among the myriad approaches, a differentiated learning

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has