Course Description

Vacuum Process Fundamentals introduces the learner to casting production by Vacuum Process Molding. The course provides an overview of the common defects and troubleshooting guidelines. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment processing steps associated with their profession.

Who will benefit from this Vacuum Process course?

Companies, individuals, or educational institutions that require an understanding of the equipment, processes, and post-processes involved in producing castings by vacuum process molding.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Vacuum Process Fundamentals

*upon successful completion

Related Posts

Exploring the Differences Between Casting and Forging

Differences Between Casting and Forging In the world of manufacturing, few processes can match the intricate artistry and skilled precision of casting and forging, which

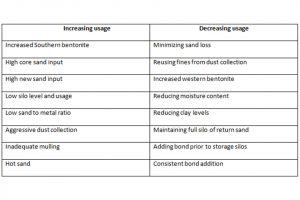

Reducing Bond Usage in Green Sand Systems

This month, let’s learn all about some effective ways of reducing bond usage in green sand systems. Firstly, bond is added to green sand systems

How Can THORS Help Enhance Your College Education?

How Can THORS Help Enhance Your College Education? THORS Academy can help enhance your college education in a number of ways. Imagine being in a