Course Description

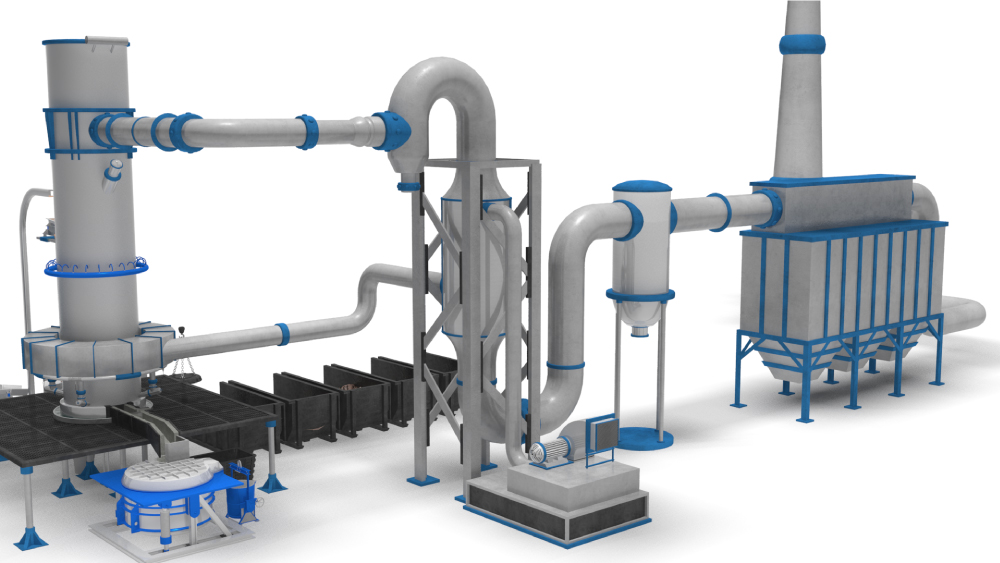

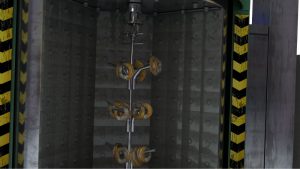

The Cupola Furnace Fundamentals course provides learners a comprehensive overview of the basic elements of a cupola. Using graphics and animations, users are able to learn more about the functions of the main furnace components, as well as the cupola’s ancillary systems and assistive devices. The course also discusses the different instrumentation, fuels, and charge materials that may be used to operate the cupola.

Who will benefit from this Cupola Furnaces course?

Foundries that operate cupolas; Organizations that sell raw materials and equipment, or offer services for cupolas.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cupola Furnace Fundamentals

*upon successful completion

Related Posts

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

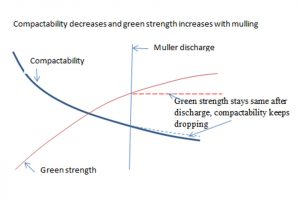

How to Control Compactability of Sand

Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and controlling the factors affecting it.

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.