Course Description

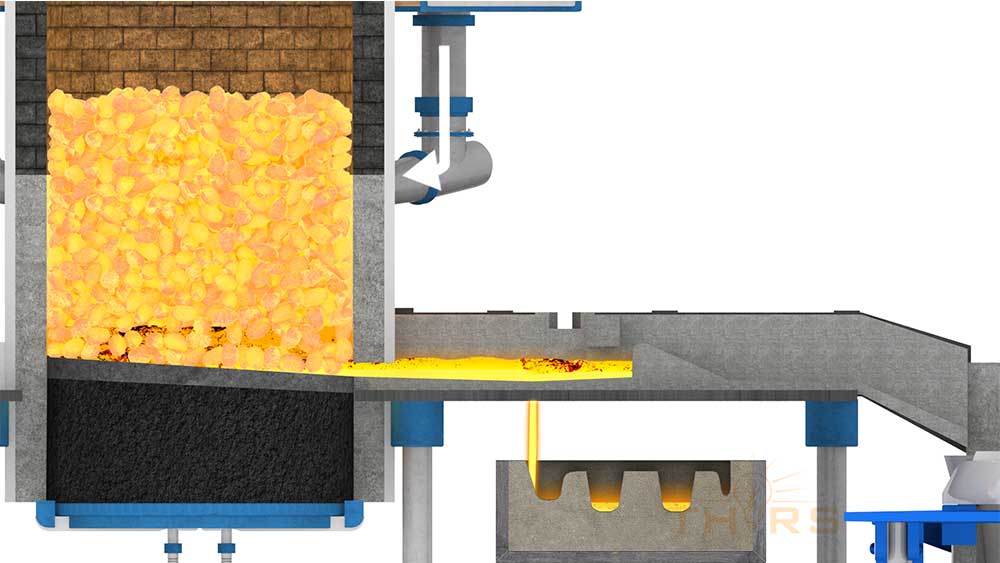

The Cupola Furnace Operations course aims to provide cupola operators and other interested individuals a basic understanding of the cupola furnace and how it operates. This course focuses on the melting process of the cupola, its method of heat transference, as well as the chemical reactions and gas reactions that occur within the furnace. There is also an examination of cupola turnaround procedures, operating procedures, and control tests that should be performed to run the cupola efficiently and consistently.

Who will benefit from this Cupola Furnace Operations course?

Foundries that operate cupolas; Organizations that sell raw materials and equipment, or offer services for cupolas.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cupola Furnace Operations

*upon successful completion

Related Posts

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry

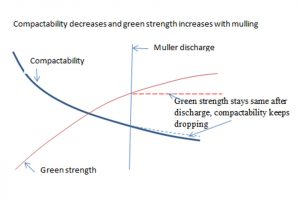

How to Control Compactability of Sand

Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and controlling the factors affecting it.