Course Description

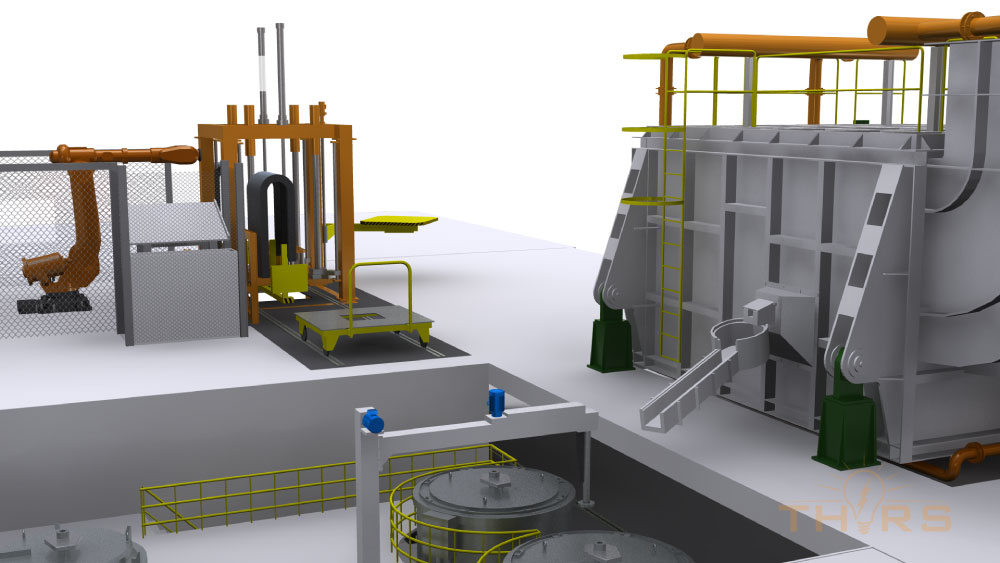

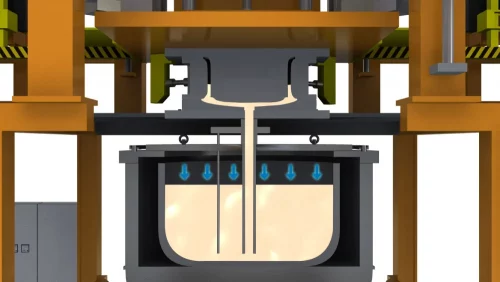

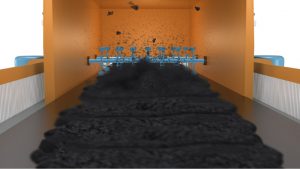

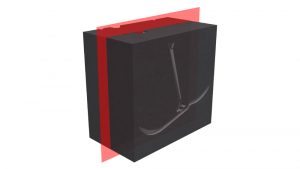

Low Pressure Die Casting Basics provides an introduction to the terminology, equipment, and processing steps associated with low pressure die casting. Presented in THORS’ highly visual and interactive learning format, this course will improve process knowledge for employees in low pressure die casting foundries.

Who will benefit from this Low Pressure Die Casting course?

Companies, individuals, or educational institutions who wish to more clearly understand the terminology, equipment, and processing steps associated with low pressure die casting

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Low Pressure Die Casting Basics

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures