Course Description

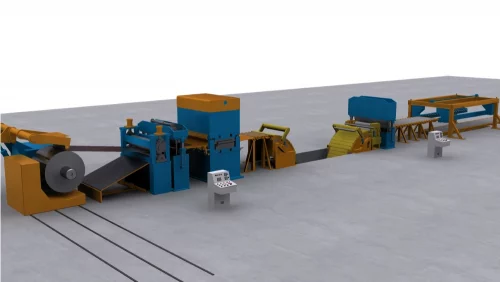

Corrective Leveling Basics provides learners with a basic understanding of the concepts and equipment, terminology, and troubleshooting methods that apply to corrective leveling processes for sheet metal. There are several processes that are considered “leveling”; the emphasis for this course will be the corrective leveling that is typically applied to sheet metal prior to the metal being cut-to-length and stacked.

Who will benefit from this Corrective Leveling course?

Companies, individuals, or educational institutions that purchase, manufacture, or otherwise require an understanding of corrective leveling and the cut-to-length and multi-blanking process.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Corrective Leveling Basics

*upon successful completion

Related Posts

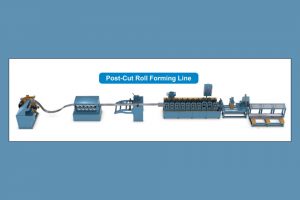

The Roll Forming Process in 7 Basic Steps

What is the roll forming process? The roll forming process is a metal-forming operation that imparts the desired shape to a material strip in a

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools