Course Description

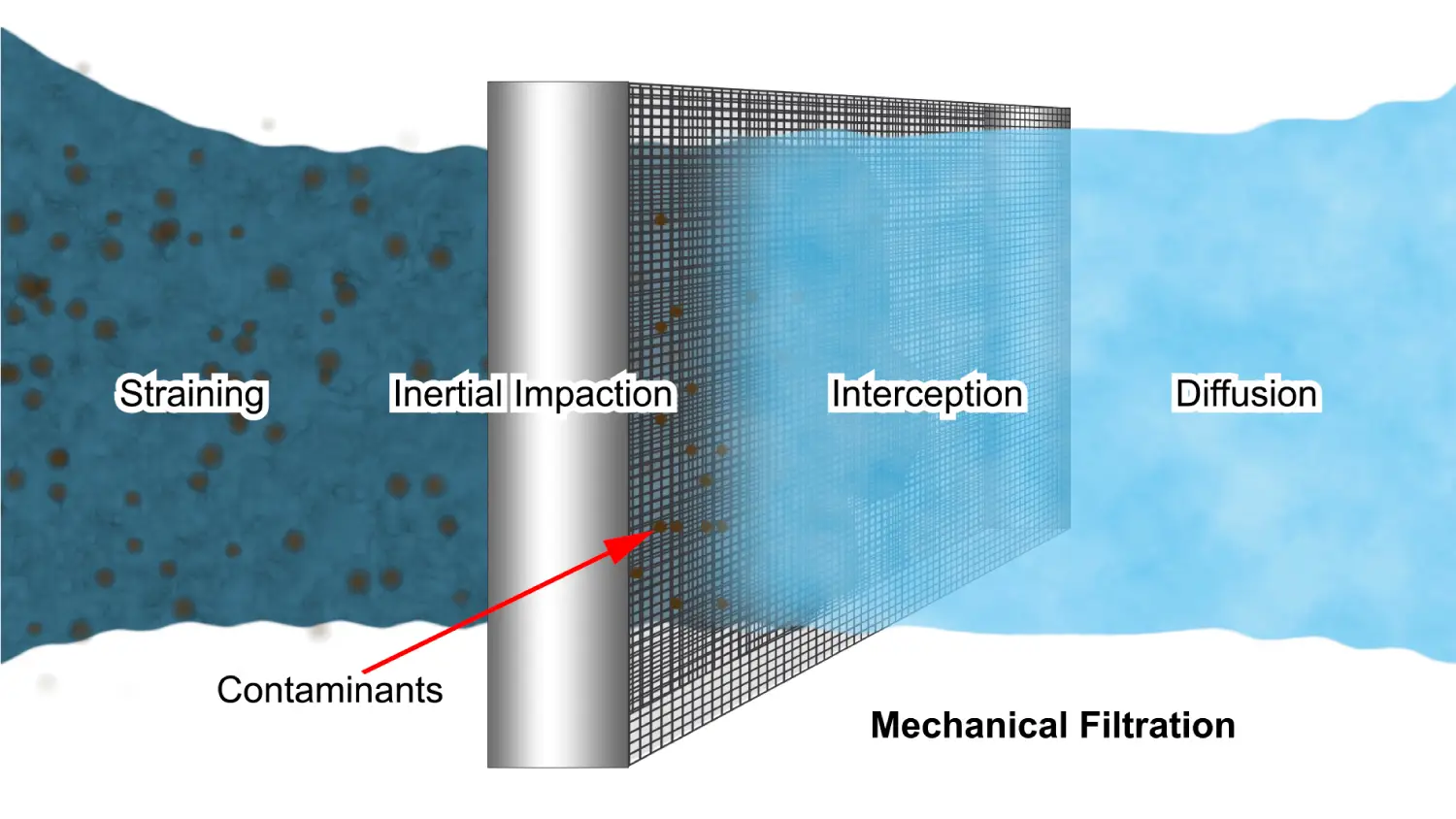

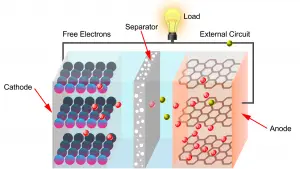

The THORS Filtration Systems for Transportation and Industrial Applications course introduces the learner to the filtration system components, filter elements, and media materials. The course covers various filtration principles, key performance attributes, and filtration system types. Presented in THORS’ visually engaging format, this course will equip the learner with an in-depth understanding of filtration systems.

Who will benefit from this filtration systems course?

Engineers, purchasing, sales, marketing, quality personnel or any learner that needs to know about filtration systems for the transportation or industrial markets, such as construction and power generation.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Filtration Systems for Transportation and Industrial Applications

*upon successful completion

Related Posts

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools