Course Description

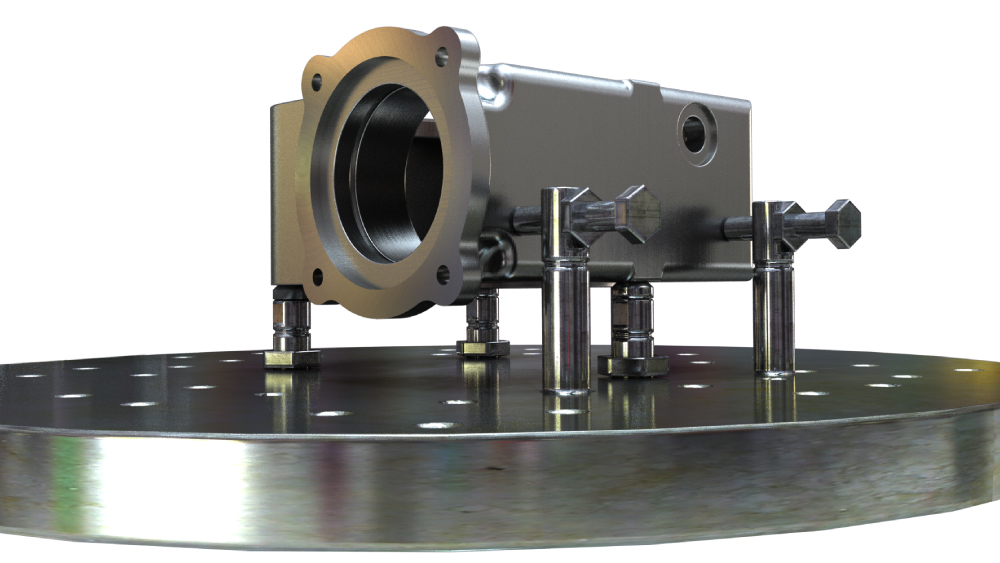

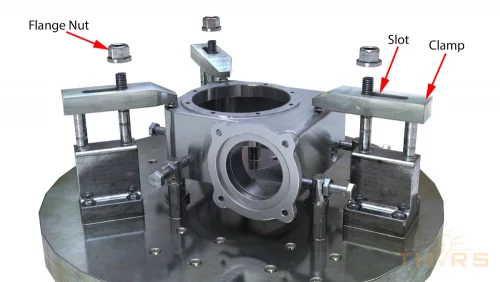

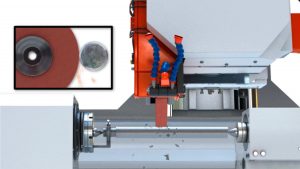

Fixturing Fundamentals for Machining introduces learners to the basic equipment, concepts, and general terminology that are often applied for fixturing or workholding. The important and yet sometimes overlooked process of metal part fixturing is brought to life in this course using realistic 3D models of actual parts. Helpful animations are also provided for concepts such as the 3-2-1 Principle and how to arrest the 12 degrees of freedom. The material in this course is beneficial to both experienced fixturing or workholding veterans and to learners new to the industry.

Who will benefit from this Fixturing for Machining course?

Organizations that utilize machining in their manufacturing process; Procurement, supplier quality, engineering, and operations personnel of organizations that design and purchase machined components.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Fixturing Fundamentals for Machining

*upon successful completion

Related Posts

Boosting Employee Engagement in eLearning

Introduction In the realm of modern workplaces, boosting employee engagement in eLearning has become a pivotal factor in fostering productivity, job satisfaction, and overall organizational

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency