Course Description

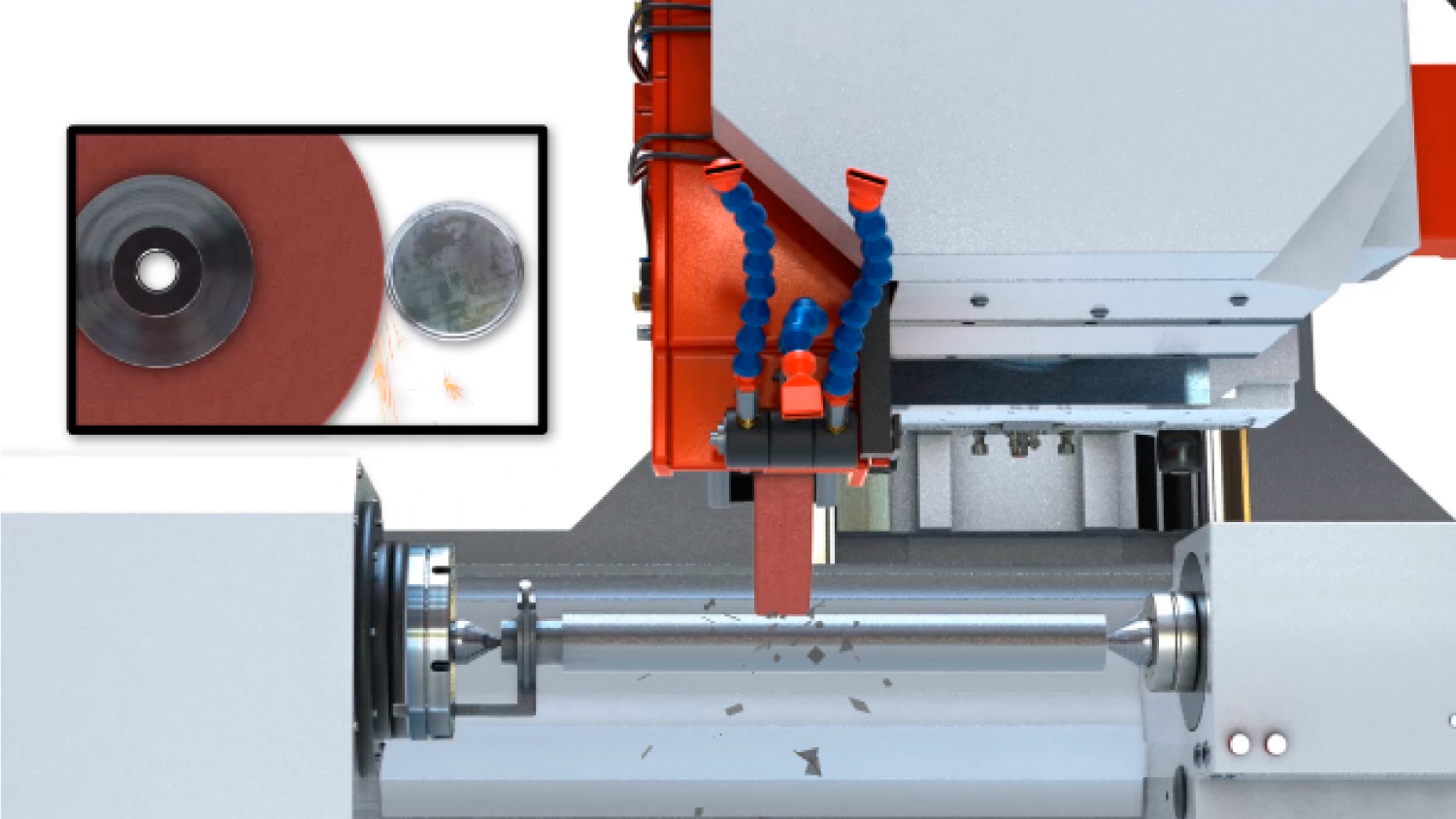

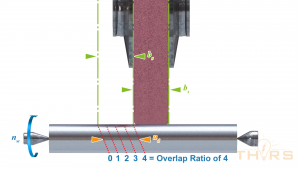

Grinding parameters are key to the cylindrical grinding processes. The surface finish of the workpiece can be improved by adjusting the grinding parameters. The THORS Cylindrical Grinding Process Parameters course provides a comprehensive understanding of the various grinding and dressing parameters of plunge and traverse grinding operations.

Who will benefit from this cylindrical grinding process parameters course?

Design engineers, product developers, operations, quality, sales, and marketing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cylindrical Grinding Process Parameters

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process

What are the Primary Gear Hobbing Cutting Parameters? Primary gear hobbing cutting parameters include the radial feed rate, the axial feed rate, the work spindle

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent