Course Description

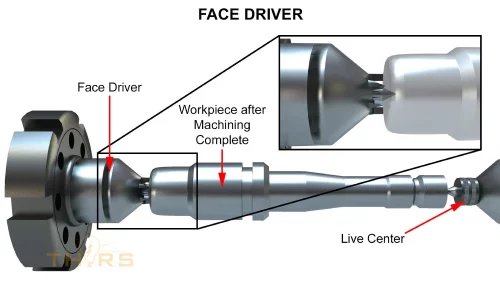

Turning Tool and Process Basics gives learners insight on the cutting tool, workholding device, and cutting operation selection process for turning centers. These topics are tailored to a level appropriate for a CNC turning center setup operator, and industry professionals seeking to understand the job functions of this role. Combining live video with animated demonstrations, this course covers everything from cutting parameters, to L/D ratio and workholding selection, to the format of canned cycles in CNC programming.

Who will benefit from this Machining Turning Tools Basics course?

Manufacturing, quality, and engineering functions in an organization that seeks to understand the process of turning.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Turning Tool and Process Basics

*upon successful completion

Related Posts

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on