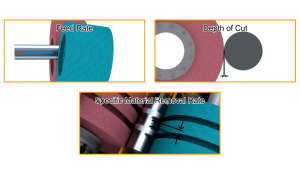

Course Description

Who will benefit from this Cylindrical Grinding course?

Manufacturing, quality, and engineering functions in an organization that machines product and procures machined components using CNC cylindrical grinders, conventional grinders, or similar equipment.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cylindrical Grinding Fundamentals

*upon successful completion

Related Posts

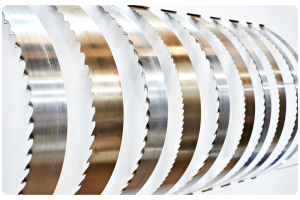

Advanced Features in Modern Industrial Band Saw Blades

Modern band saw blades are in a constant state of improvement and refinement. The ever-growing demand for these efficient cutting tools is driving manufacturers to

The Role of eLearning in Compliance Training

In today’s fast-changing business environment, effective compliance training is more crucial than ever. eLearning in compliance training has emerged as a powerful tool for ensuring

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training