Course Description

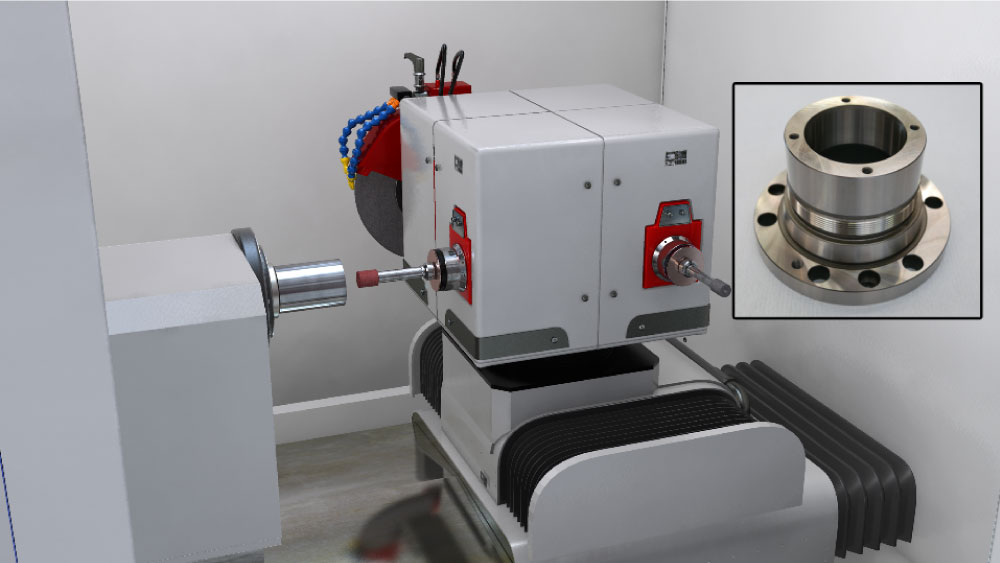

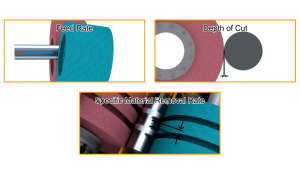

Machine Tool Fundamentals provides an introduction to the components, terminology, and capabilities of machine tools typically used in the industry. Presented in THORS’ highly visual and interactive learning format, this course will help employees in machining industries become familiar with the important equipment and terminology associated with their profession.

Who will benefit from this Machine Tools course?

Companies, individuals, or educational institutions that require an understanding of basic terminology associated with machine tools.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Machine Tool Fundamentals

*upon successful completion

Related Posts

Gears

Examining Gear Hobbing Equipment and Tools

What is gear hobbing? Gear hobbing is considered a generating process and is the most common method of producing teeth in gears of all sizes.

THORS Staff Writer

Training

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

Anshika Srivastava

Career Planning

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands

THORS Staff Writer