Course Description

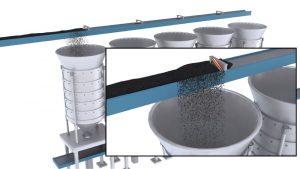

The Cupola Furnace Troubleshooting and Techniques course is an informative advance-level course for cupola operators working firsthand with a cupola furnace. The course provides operators with an introduction to the most common troubleshooting situations and practical techniques to employ when problems occur. It also focuses on the ramifications of cupola design, the benefits of operating an optimally designed cupola, as well as how to make desired changes to carbon content, spout temperature, and melt rate.

Who will benefit from this Cupola Furnace Troubleshooting course?

Cupola operators, cupola foremen, melt superintendents.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cupola Furnace Troubleshooting and Techniques

*upon successful completion

Related Posts

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands