Course Description

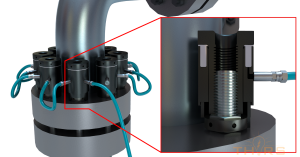

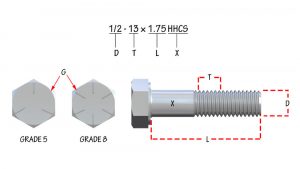

The Bolted Joint Basics course will help a learner understand the different types of physical principles that must be taken into consideration with a bolted joint, the concepts that allow a bolted joint to work, and the common tools used to assemble and control a bolted joint.

Who will benefit from this Bolted Joints course?

Quality, manufacturing, engineering, designing, testing, purchasing, and sales function at organizations that require an understanding of bolted joints, their specific characteristics, assembly methods and tools, and testing equipment used to verify and its specific characteristics.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Bolted Joint Basics

*upon successful completion

Related Posts

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has