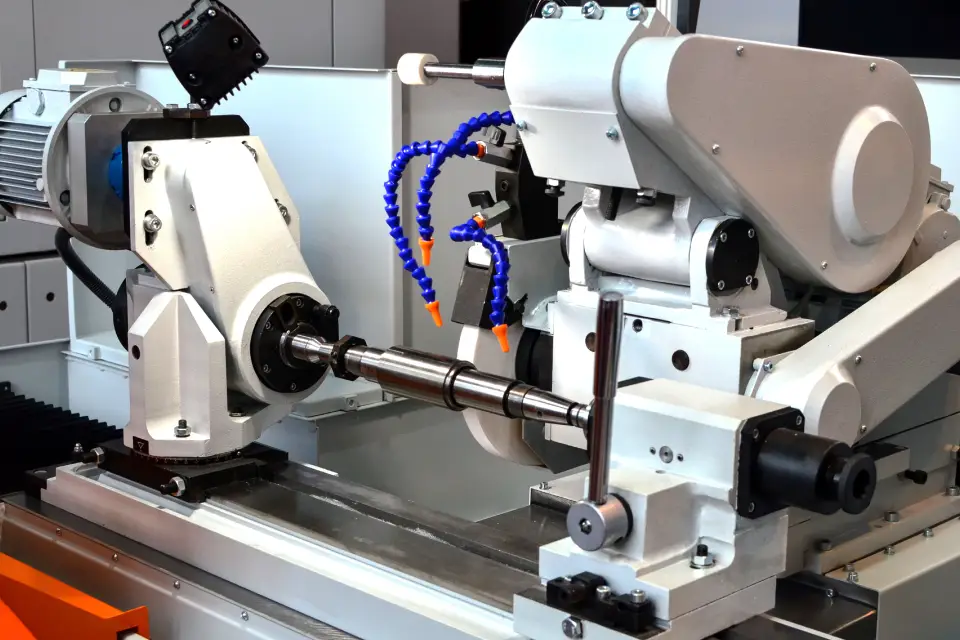

In modern manufacturing, cylindrical grinding plays a crucial role, emerging as a key process. Let’s explore the intricate world of cylindrical grinding; its diverse applications, its role across various sectors, and the technical nuances that make it a keystone for manufacturing. Here are five key factors fueling its momentum.

Applications Across Diverse Sectors

Cylindrical grinding finds extensive applications across diverse manufacturing industries. From aerospace components requiring exact specifications to crafting automotive parts, shaping intricate medical devices, and contributing to the precision of electronics, its versatility is incredible. Cylindrical grinding influences everyday consumer goods, contributes to the energy sector, and refines components crucial to mining and heavy machinery.

Achieving Micrometer-Level Precision

One of the standout features of cylindrical grinding is its ability to achieve micrometer-level precision. In aerospace manufacturing, where safety is paramount, and in the automotive sector, where performance is critical, the precision offered by cylindrical grinding ensures that components meet exact specifications, contributing to the reliability and functionality of the product.

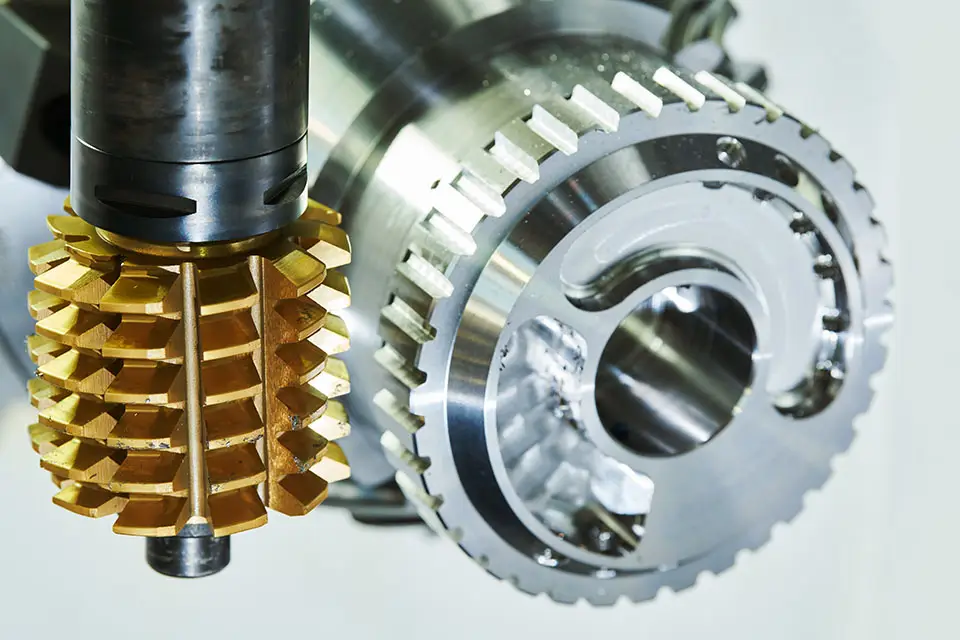

Versatility in Material Mastery

Cylindrical grinding is suited to many materials and a variety of purposes. Whether working with metal alloys, ceramics, or composites, this technique can be tailored to suit the unique characteristics of each material. This adaptability makes cylindrical grinding an invaluable tool for manufacturers dealing with a diverse range of materials in their production processes.

Enhancing Manufacturing Efficiency

In addition to a high level of precision, cylindrical grinding enhances overall manufacturing efficiency. By producing components with minimal variation and consistent quality, manufacturers can streamline assembly processes, reduce waste, and optimize the cost-effectiveness of their operations.

Eco-Friendly Manufacturing Practices

An often-overlooked aspect is cylindrical grinding’s contribution to sustainable and eco-friendly manufacturing practices. The precision it offers helps minimize material waste, and its role in crafting components that enhance the energy efficiency of machinery aligns with the broader goal of environmental responsibility in manufacturing. This added dimension positions cylindrical grinding as a conscientious choice for companies aiming to adopt greener practices in their operations.

Conclusion

The supremacy of cylindrical grinding’s excellence is underscored by its five key attributes. As industries continue to evolve, cylindrical grinding becomes foundational, driving innovation and setting new standards for precision manufacturing.

THORS eLearning Solutions has multiple courses on cylindrical grinding, including topics such as: fundamentals, process parameters, and process strategy, as well as a video series. Check them out today!