Cylindrical Grinding Innovations

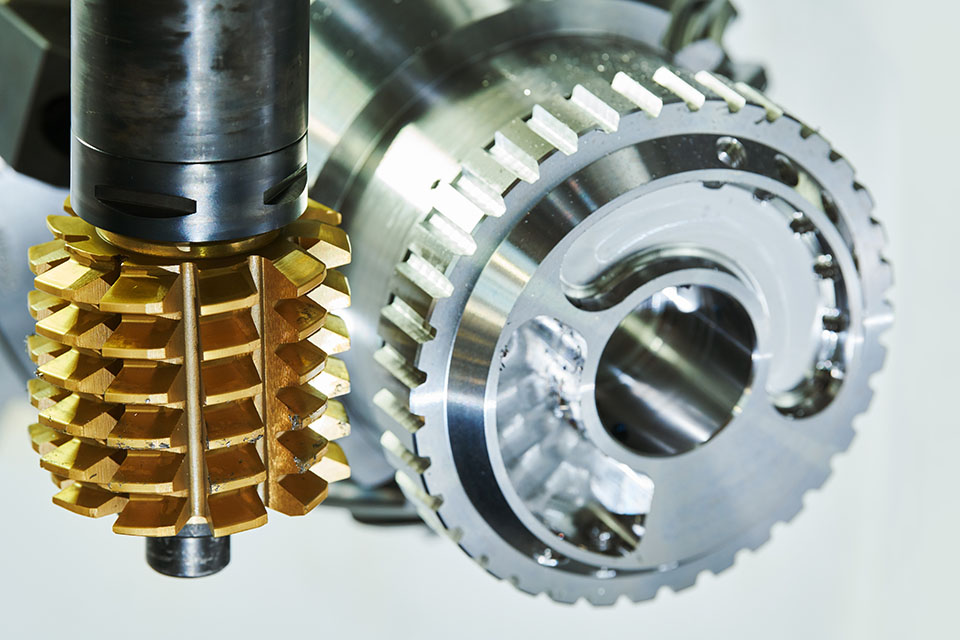

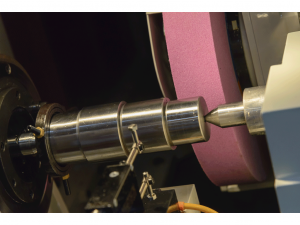

Cylindrical grinding innovations have revolutionized the machining process. Cylindrical grinding is a machining process used to achieve high levels of dimensional accuracy and enhanced surface finish in cylindrical workpieces. It involves using a grinding wheel with abrasive particles bonded together to remove material from the workpiece. Cylindrical grinding is commonly used in industries such as automotive, aerospace, and manufacturing for producing precision components with tight tolerances. In line with technological advancements in manufacturing, cylindrical grinding is witnessing significant improvements that entail a fusion of cutting-edge technology, sustainability, and precision. Let’s delve into the innovations that are redefining the future of cylindrical grinding.

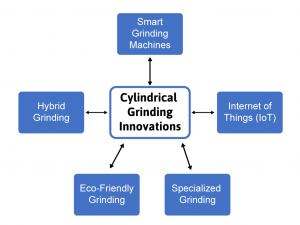

Smart Grinding Machines

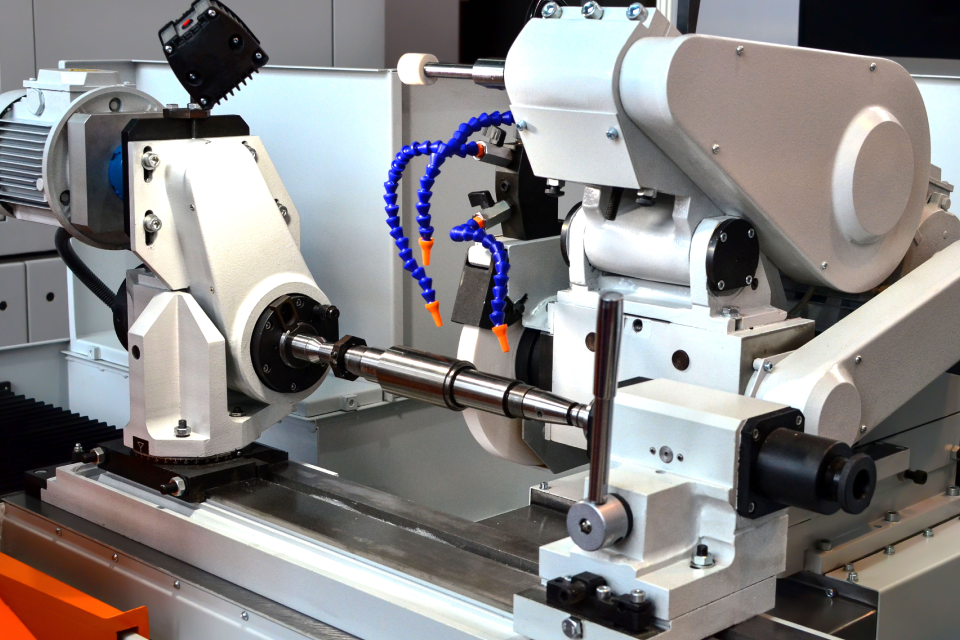

Smart cylindrical grinding machines powered by Artificial Intelligence (AI) and automation can quickly analyze real-time data from the grinding process. This allows them to adjust essential parameters, like wheel speed and feed rate. The adjustments are set to significantly reduce the time it takes to complete each cycle, improve product quality by minimizing errors, and ultimately simplify operations while improving productivity.

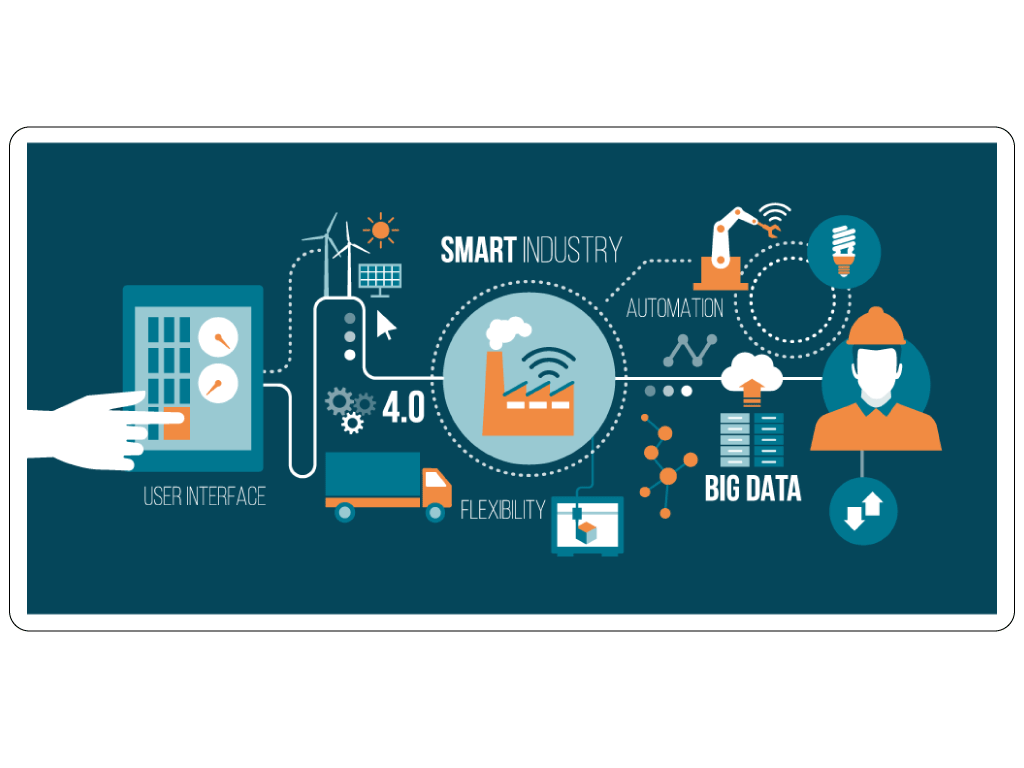

Internet of Things (IoT)

The IoT (Internet of Things) and Industry 4.0 principles are rolled into cylindrical grinding innovations. The remarkable advancement in cylindrical grinding involves the integration of IoT and Industry 4.0 principles, creating a network of interconnected machines that seamlessly share information. This sharing of data facilitates predictive maintenance. Additionally, remote monitoring allows operators to check and adjust machine parameters from a central control panel, much like adjusting a thermostat remotely. This merging of technologies enhances operational efficiency and empowers industries to achieve higher levels of productivity and precision.

Specialized Grinding

The utilization of advanced abrasives, such as Cubic Boron Nitride (CBN) and diamond abrasives, is growing. These materials provide exceptional hardness and thermal conductivity, making them ideal for grinding challenging materialssuperalloys. High speed grinding techniques are becoming more prevalent in specialized grinding. This is facilitated by advancements in machine capabilities and control systems, enabling higher material removal rates and improved surface quality. The rise of advanced a challenge for the grinding industry. To tackle this, specialized grinding wheels and techniques are used to achieve high precision and superior surface finishes.

Eco-Friendly Grinding

Within cylindrical grinding innovations, there’s a growing focus on sustainability. It means adopting practices that are kind to the environment. This involves optimizing coolant usage, implementing energy-efficient measures, and developing strategies to reduce waste. The manufacturing industry is keen on adopting these sustainable processes to minimize their environmental footprint while maintaining precision in cylindrical grinding operations, ensuring a greener, more responsible approach within the industry.

Hybrid Grinding

Hybrid grinding, which is a fusion of traditional abrasive grinding with other machining processes, such as milling or turning, integrated in the same machine, is gaining popularity. The integration of multiple processes makes it possible to produce complex cylindrical workpieces efficiently and accurately, meeting the evolving needs in the world of cylindrical grinding. Hybrid grinding offers numerous advantages, including improved surface quality, increased material removal rates, and enhanced productivity.

For professionals and enthusiasts eager to stay ahead in this evolving landscape, staying informed and educated is key. If you’re looking to deepen your understanding of these cylindrical grinding innovations and their applications in the world of machining, visit THORS.com. Here, you’ll find a wealth of resources and courses tailored to help you navigate the complexities of modern manufacturing processes. Join us at THORS to explore the latest trends and technologies in cylindrical grinding, and equip yourself with the knowledge to excel in this dynamic field.

Discover the future of machining at THORS.com – where innovation meets expertise.