Course Description

The THORS Process Failure Mode and Effects Analysis course equips learners to identify potential failure modes, create an effective PFMEA, and maintain the PFMEA. Gain a thorough understanding of PFMEA and prioritize risks, devise corrective actions, and satisfy customer requirements.

Who will benefit from this PFMEA course?

Marketing, Sales, Design, Engineering (Product and Process), Purchasing, Manufacturing, Quality and Service functions at organizations that require an understanding of a process failure mode and effects analysis, or PFMEA. Any learner who is required to understand and use the PFMEA.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Process Failure Mode and Effects Analysis

*upon successful completion

Related Posts

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

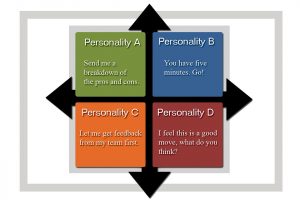

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the