Course Description

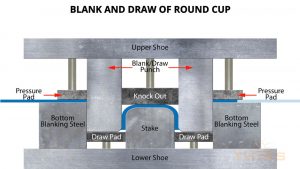

Stamping Processes introduces learners to the various stamping processes. The material in this course is beneficial to both seasoned stamping experts and learners new to the industry.

Who will benefit from this Stamping Processes course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that perform stamping operations. Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Stamping Processes

*upon successful completion

Related Posts

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

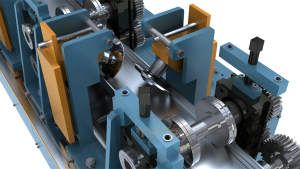

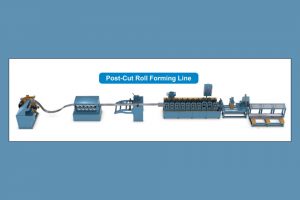

The Roll Forming Process in 7 Basic Steps

What is the roll forming process? The roll forming process is a metal-forming operation that imparts the desired shape to a material strip in a