What are the basic properties of green sand?

Understanding the basic properties of green sand and the equipment required to operate a green sand foundry are important for anyone in related casting industries. Green sand molding, also referred to as clay-bonded sand molding, is the most widely used type of “bonded sand” in modern foundries worldwide. Molten metal is poured into green sand molds and solidified in the required shape and design. Cast metal parts, or “castings,” are used in many commercial and industrial applications, including vehicle parts, cookware, construction equipment, and much more.

What is an example of a green sand molding system?

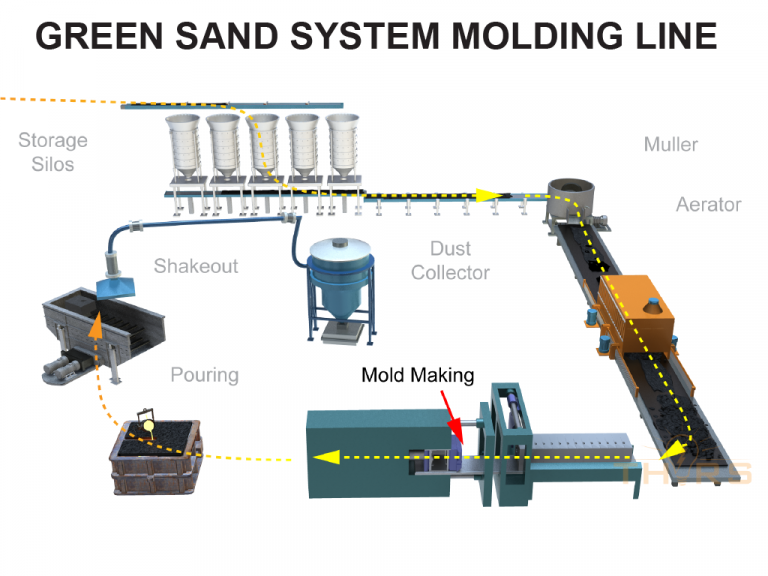

There are several important processing steps involved in a green sand foundry system. The number of machines or units used in a foundry depends on the size and capacity of the operation. The common green sand processing stations include:

- Storage silos, which are sand holding and dispensing units,

- Mullers, which are mixing units for sand, clay, water, and other additives,

- Aerators, which are sand conditioning units that “aerate” the mixed sand,

- Mold making, which takes place in mold production units that form the sand molds,

- Pouring, which is where molten metal is poured into the formed sand molds,

- Shakeout, which is where the now formed “casting” is separated from the sand mold, and the

- Dust collector, which is an air filtration system.

The green sand is collected after the shakeout process and recycled through the system.

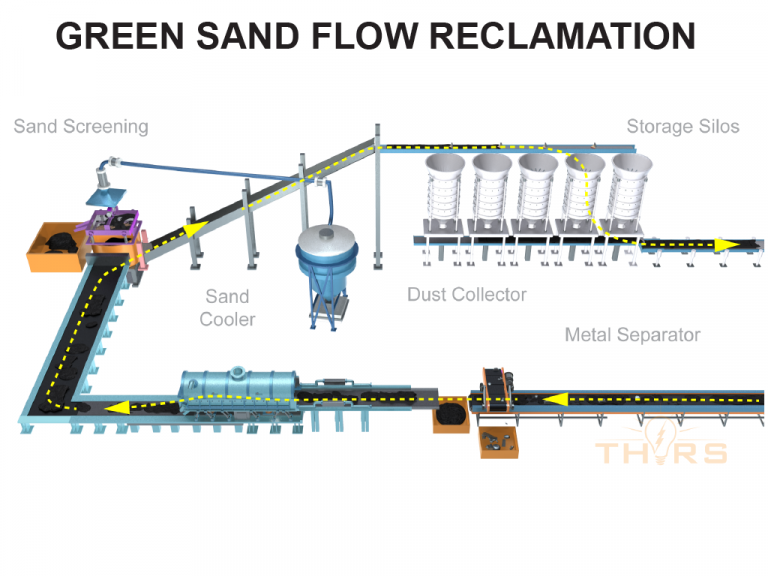

What is an example of a green sand reclamation system?

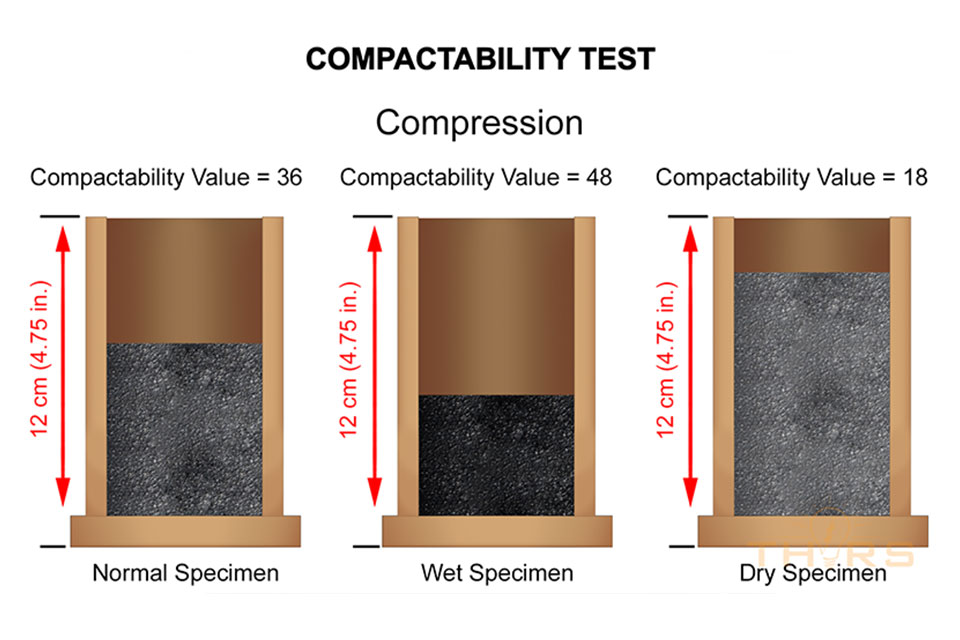

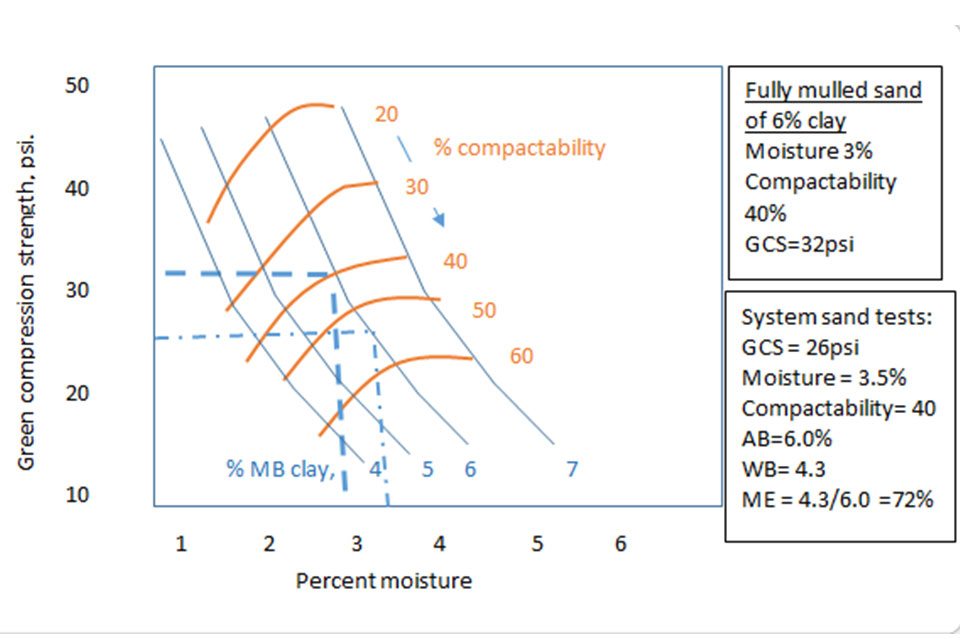

Reclaimed sand, often referred to as return sand, is recycled through the system after the casting process so that it can be reused to create more castings. The specifics of this process depend on a variety of factors, such as the compactability of the sand. The common sand reclamation stations include:

- Metal separators, which are magnetic systems that separate metal inclusions from the return sand,

- Sand coolers, which are machines used to reduce the temperature of return sand,

- Sand screening, which are units that separate the sand based on grain size,

- Dust collection, which is an air filtration system that collects particles, and

- Storage silos, which are sand holding and dispensing units.

Learn more about green sand foundry equipment and systems in THORS’ Green Sand System Equipment & Process Control course.