How can you determine whether composites are better than metals for a project? Here is a summary of the differences between composites and metals and a handy list of aspects you can use to compare the two.

What is a composite?

The best way to see the differences between composites and metals is to first explain what a composite is. Composites are, at their most basic, the combining of two materials together to create a third material with specific characteristics. This means there are an overwhelming number of options and combinations. Composites can occur naturally, or they can be manufactured.

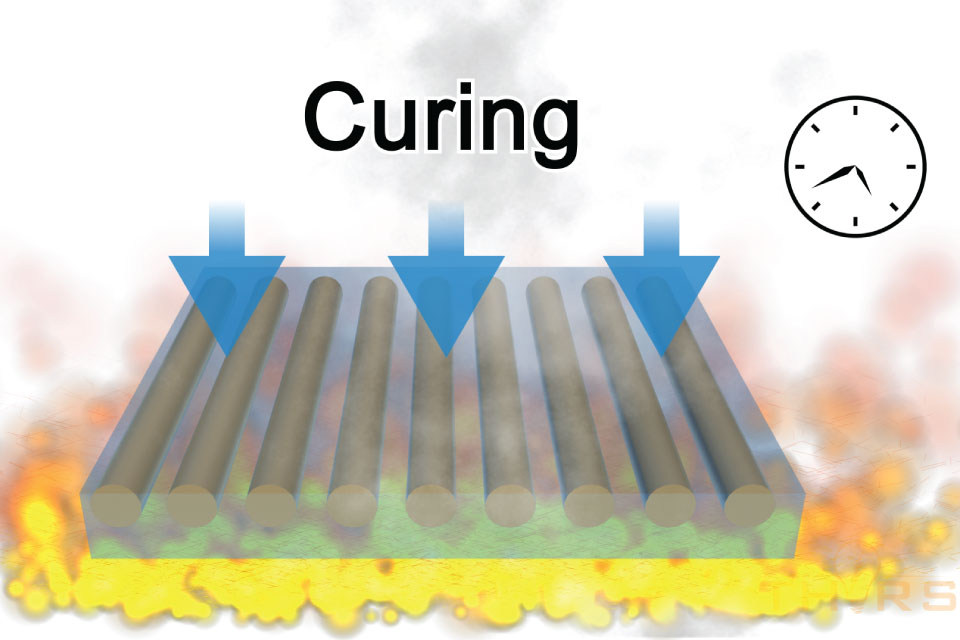

In manufacturing, once the two materials are combined, they are heated or cured so that the two materials synthesize completely. Now you have a new material with its own properties and enclosed in a protective barrier of some kind, depending on the material. For example, plywood is a man-made composite that is typically covered in some kind of sealant, like paint, which acts as its protective barrier. Composites are used across many industries in creating parts for things like airplanes, cars, and boats which, in past years, may have used metals for these parts.

How are metals different from composites?

When metals are blended, they are called alloys. Metals and alloys have completely different properties from composites and are used for different projects. Everything from the production process to stiffness, the directional property, to whether or not they corrode is different between metals and composites.

How do you determine if a composite is better than a metal?

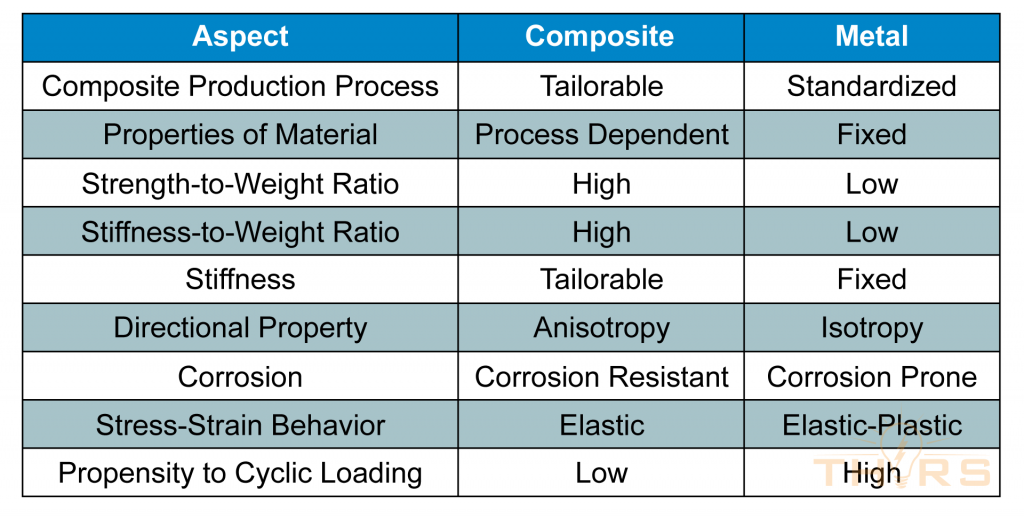

There are many ways to show the differences between composites and metals. To help you determine whether composites might be a better choice than metals, here is a handy reference with definitions of common aspects used in the various industries.

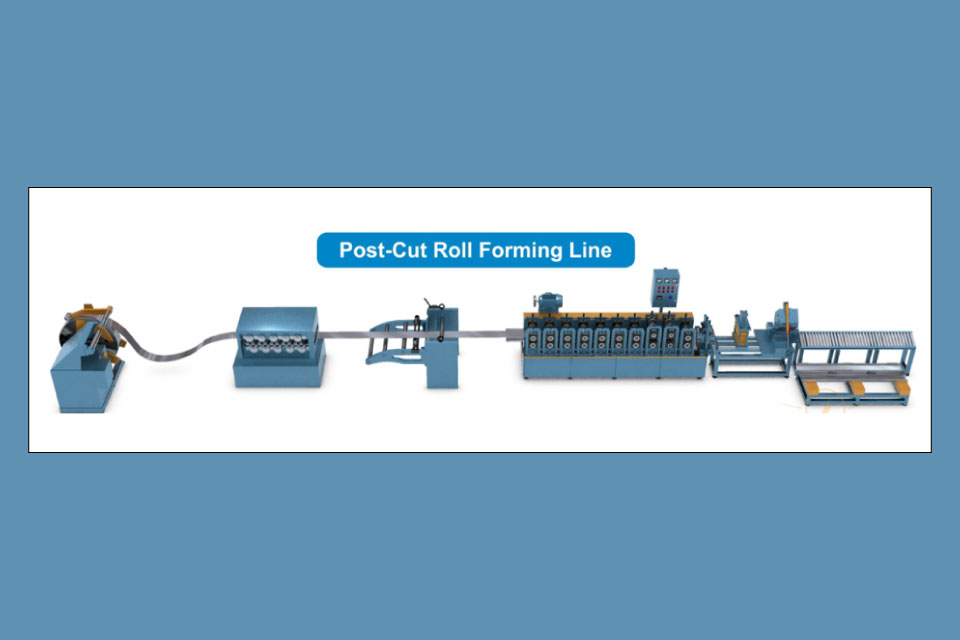

- Composite Production Process refers to how the composite or metal is produced. Composites are designed and therefore tailorable throughout every step of the process. Metal is processed in several set ways and cannot be tailored.

- Properties of Material can be decided upon and planned for during the design process for composites. Metals have standard alloy blends and standard properties that cannot be altered.

- Strength-to-Weight Ratio describes how strong a composite or metal is in relation to how much the part weighs. Composites can be designed to be both lightweight and strong, whereas strong metals tend to be heavier.

- Stiffness describes how much a part yields when a load is placed on it. High stiffness, which a composite may be designed to have, means the part yields or bends very little, if at all, when a load is placed on it. Metal has a fixed level of stiffness which differs from metal to metal and alloy to alloy.

- Stiffness-to-Weight Ratio describes how the stiffness of a composite or metal may impact the weight of the part. Composites are able to be designed for high stiffness and low weight, but the stiffer a metal part is, the heavier it is.

- Directional Properties in composites are anisotropic, so composites may have different properties in each direction, also called non-homogeneous. Metals on the other hand are isotropic, so their properties are the same in all directions, or they are homogeneous.

- Corrosion is typically not a problem for composites which can be designed with corrosion resistance in mind. Metals however are prone to corrosion.

- Stress-Strain Behavior refers to how a part responds when a load is placed upon it. A certain amount of deformation, whether stretch or shrinkage, is expected to occur. Composites act in an elastic fashion, allowing for a load without breakage. Metal acts in an elastic-plastic fashion, meaning load may push the metal part to the breaking point.

- Propensity to Cyclic Loading means a part allows for repeated use in being loaded. Composites are not as able to withstand many consecutive loads. Metal may be better able to endure taking on one load after another.

Are composites used more than metals?

Composites are more likely to be used in many modern projects such as cars and airplanes due to their flexibility in design and properties. Ultimately, the differences between composites and metals mean it would be more advantageous to use composites than to use metals in most industries.