Course Description

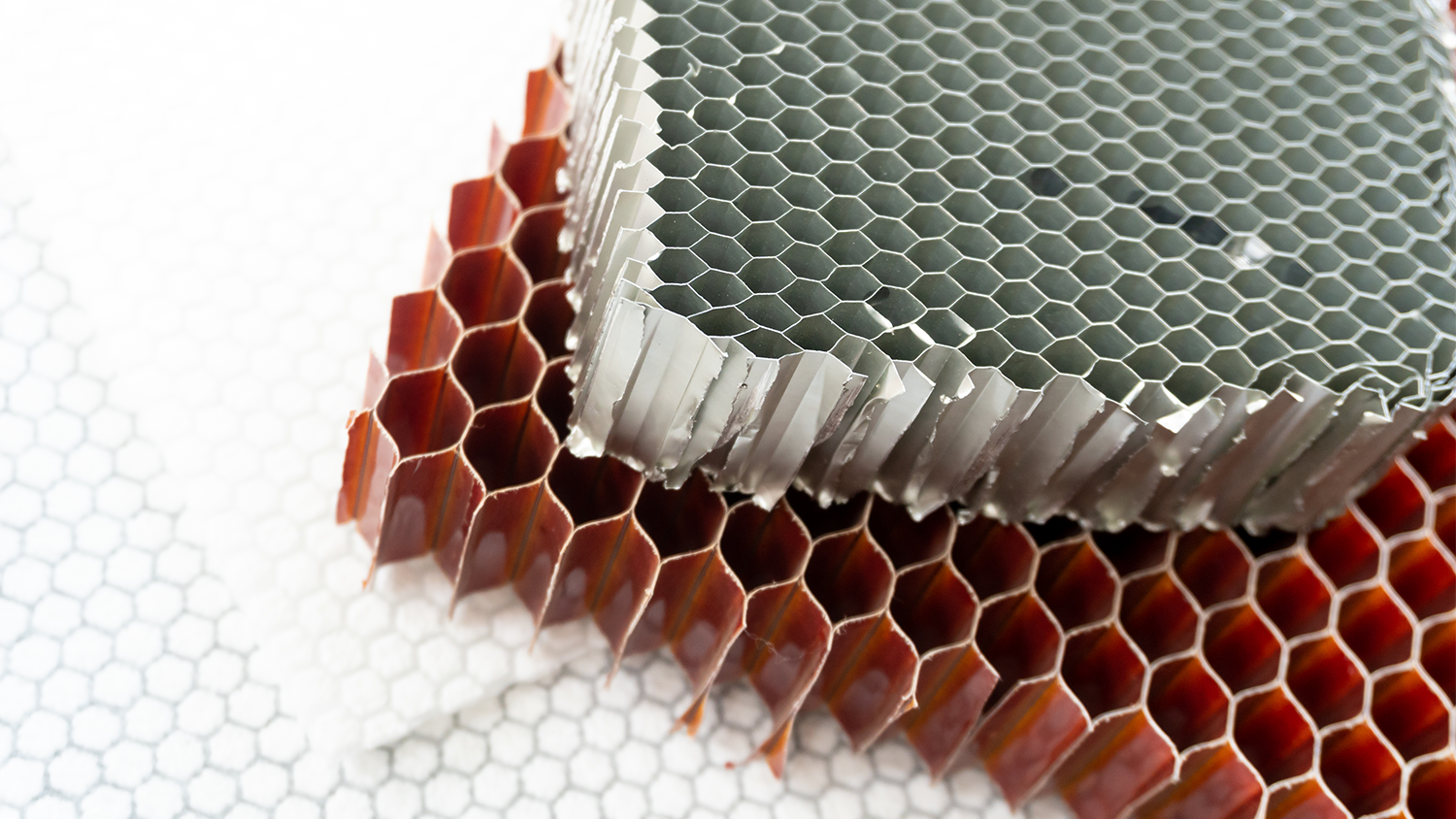

The Composite Basics course is a materials course that covers basic composite information on creating a composite, and how composites are designed. Part design covers all aspects of materials, fabrication methods, operating environs, and surrounding structure protection. Material selections are also presented, to include matrix types, material forms and core materials.

Learning Hours: 3

Who will benefit from this Composite course?

Anyone in design engineering, quality, manufacturing engineering, sales, purchasing; anyone without basic composites knowledge.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Composite Basics

*upon successful completion

Related Posts

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training