Course Description

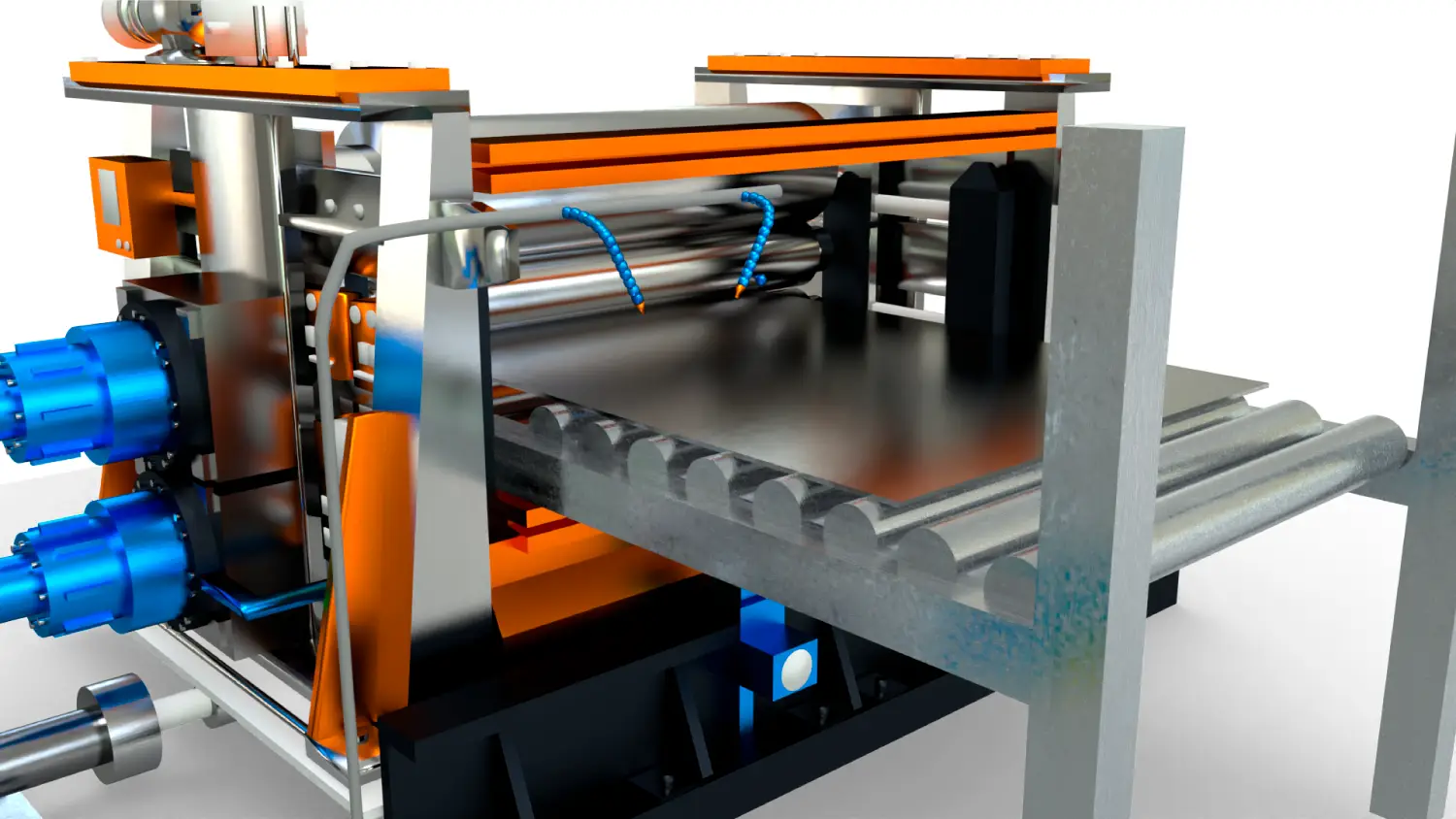

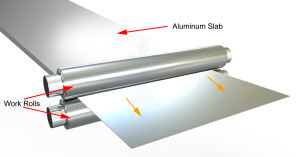

The THORS Aluminum Rolling Basics course covers the major components of a rolling mill, the support systems essential for operation, and the auxiliary equipment commonly used in production. In addition, the course provides detailed explanations of the rolling process, including both the process steps and the final finishing steps. Presented in THORS’ highly visual and interactive learning format, this course helps learners develop a clear, well-rounded understanding of how aluminum rolling is performed in a rolling mill.

Who will benefit from this aluminum rolling course?

Sales, Purchasing, Manufacturing Engineering, Quality, and Design Engineering

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Aluminum Rolling Basics

*upon successful completion

Related Posts

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent

The Roll Forming Process in 7 Basic Steps

What is the roll forming process? The roll forming process is a metal-forming operation that imparts the desired shape to a material strip in a

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry