Course Description

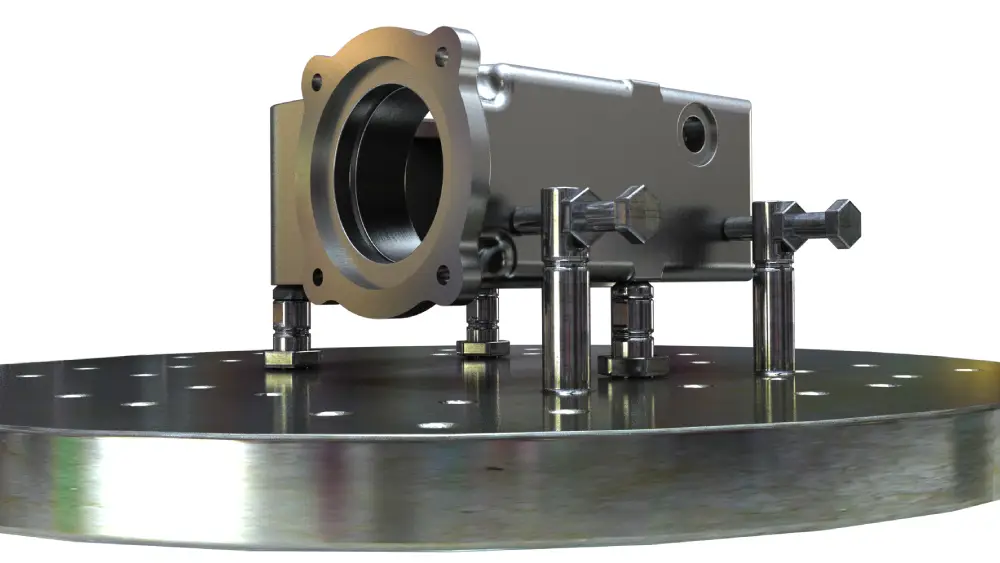

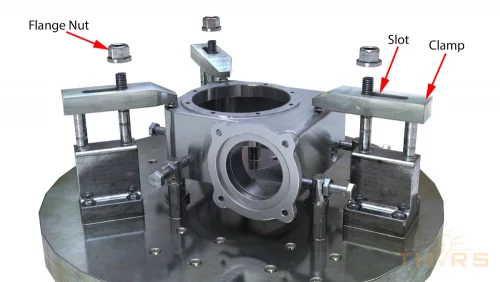

Fixturing Fundamentals for Machining introduces learners to the basic equipment, concepts, and general terminology that are often applied for fixturing or workholding. The important and yet sometimes overlooked process of metal part fixturing is brought to life in this course using realistic 3D models of actual parts. Helpful animations are also provided for concepts such as the 3-2-1 Principle and how to arrest the 12 degrees of freedom. The material in this course is beneficial to both experienced fixturing or workholding veterans and to learners new to the industry.

Who will benefit from this Fixturing for Machining course?

Organizations that utilize machining in their manufacturing process; Procurement, supplier quality, engineering, and operations personnel of organizations that design and purchase machined components.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Fixturing Fundamentals for Machining

*upon successful completion

Related Posts

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

Training Perspective: Looking Back to Look Ahead

Companies are constantly reviewing ways to reduce costs and keep positive margins. During times of economic recession, external pressures from competitors as well as internal pressures