Course Description

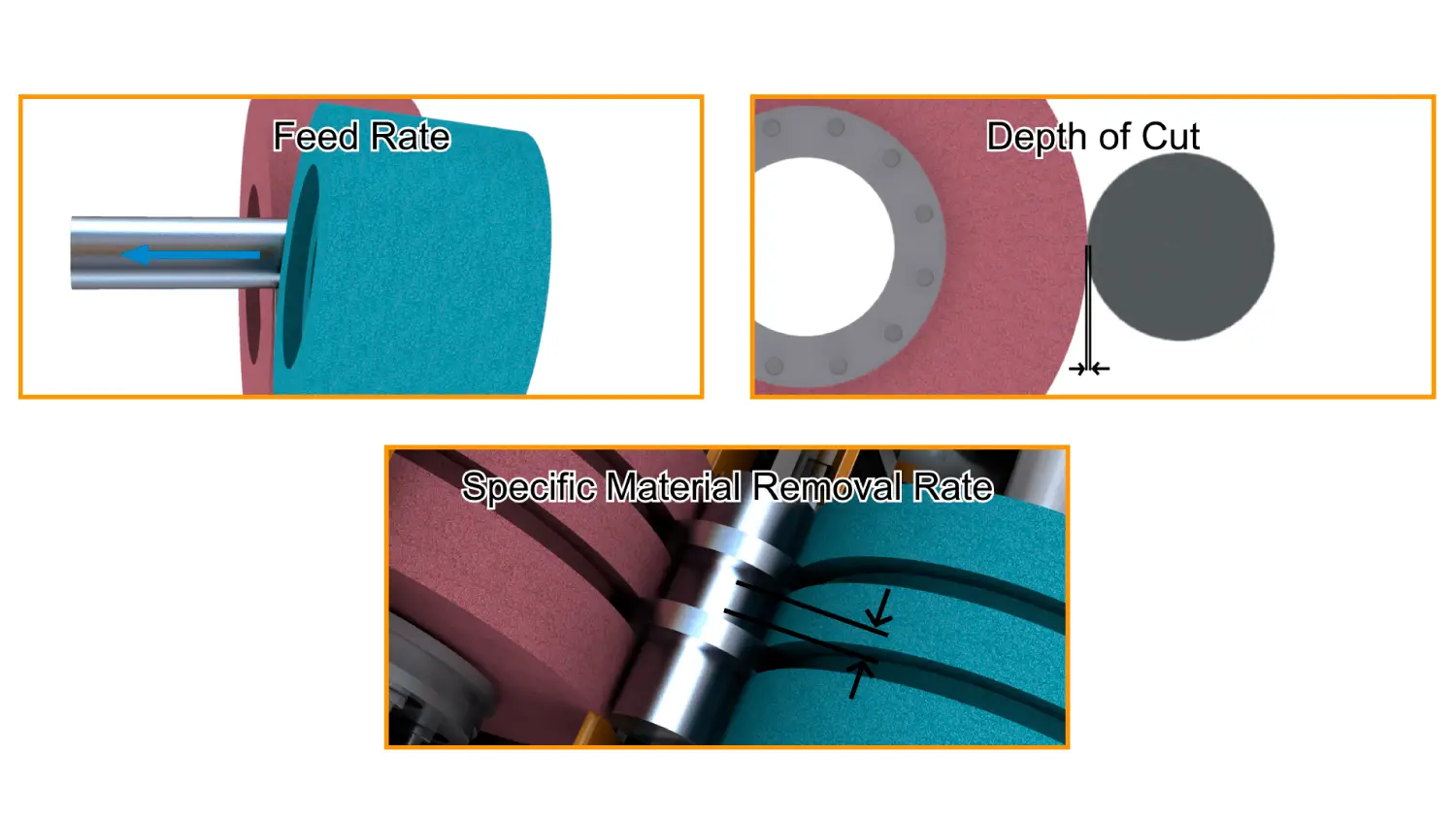

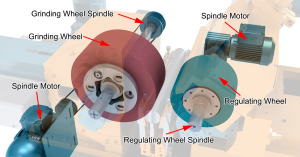

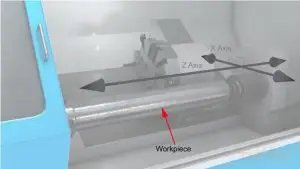

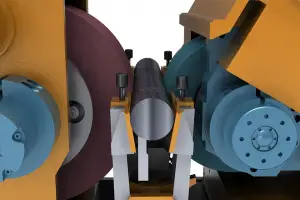

The THORS Centerless Grinding II course offers a detailed overview of grinding parameters, including the setup and adjustment of grinding and regulating wheels, workblade, and cutting parameters. It also covers various dressing tools and their respective parameters. Finally, the course explores the comprehensive setup of centerless grinding machines.

Who will benefit from this centerless grinding parameters course?

Manufacturing Engineers, Design Engineers, Estimating Teams, Quality, Purchasing, Small Business Owners, and others at organizations that operate gear centerless grinding machines will benefit from the generating gear grinding course.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Centerless Grinding II Parameters

*upon successful completion

Related Posts

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.

Understanding and Eliminating Chatter Marks in Centerless Grinding

Chatter marks in centerless grinding pose a significant concern due to the process’s continuous and high precision nature, where even minor instabilities can lead to

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on