Course Description

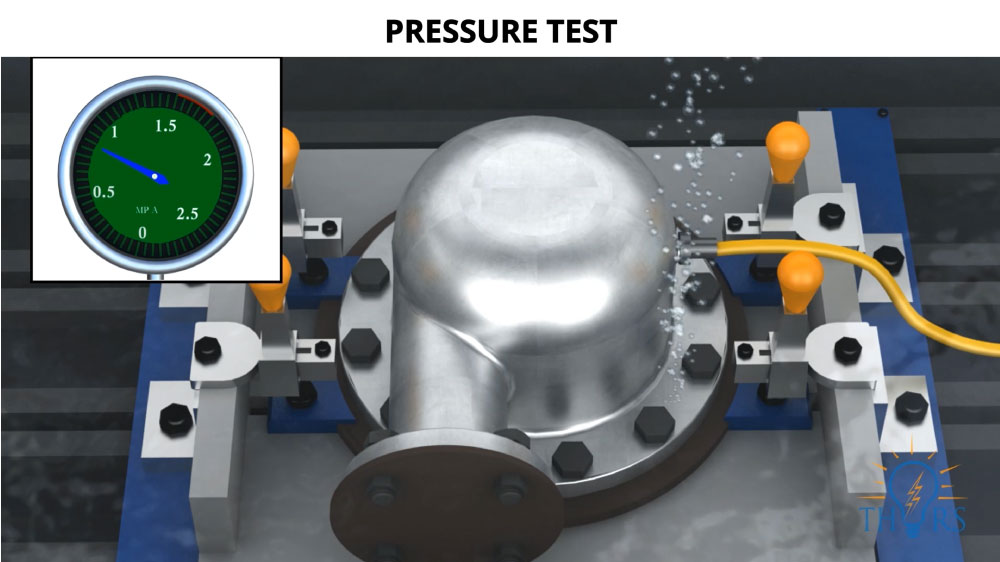

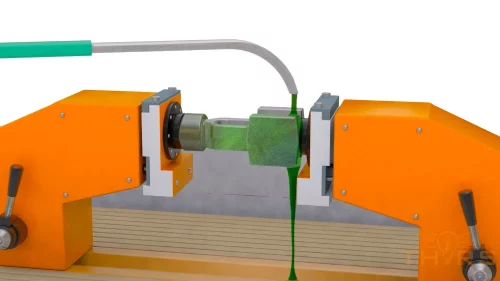

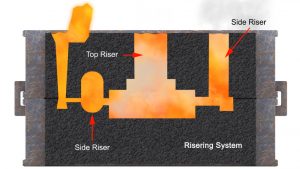

The Quality Inspection for Steel Castings course details some of the more common methods used to evaluate a steel casting for compliance to a customer’s specification requirements. Relevant for quality and inspection roles, this course focuses on the most common quality non-conformances observed during the visual inspection of steel castings and standard non-destructive testing (NDT) methods used for casting evaluation.

Who will benefit from this Steel Castings Quality Inspection course?

Foundries that pour steel; Customers who purchase steel castings; Organizations that sell material, equipment, and services to steel foundries.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Quality Inspection for Steel Castings

*upon successful completion

Related Posts

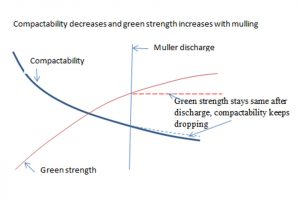

How to Control Compactability of Sand

Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and controlling the factors affecting it.

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

How to Make Your Home Learning Environment Top Notch!

Since COVID shutdowns and the work from home revolution, there’s been a lot of discussion about making a home space conducive to working. But what