Course Description

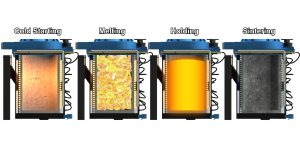

The THORS Induction Melting Furnace I course introduces the principles behind induction heating and melting, the important parts of induction furnaces, and the typical furnace modes of operation. Presented in our interactive Lightning Learning format, this course helps learners make visual connections with the various components and concepts involved in modern induction melting.

Who will benefit from this Induction Melting Furnace course?

Foundry Melt Deck Supervisors and Operators, Manufacturing Engineering, Maintenance Personnel, Quality Personnel

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Induction Melting Furnace I

*upon successful completion

Related Posts

Exploring Induction Melting Furnace Components: The Essential Guide

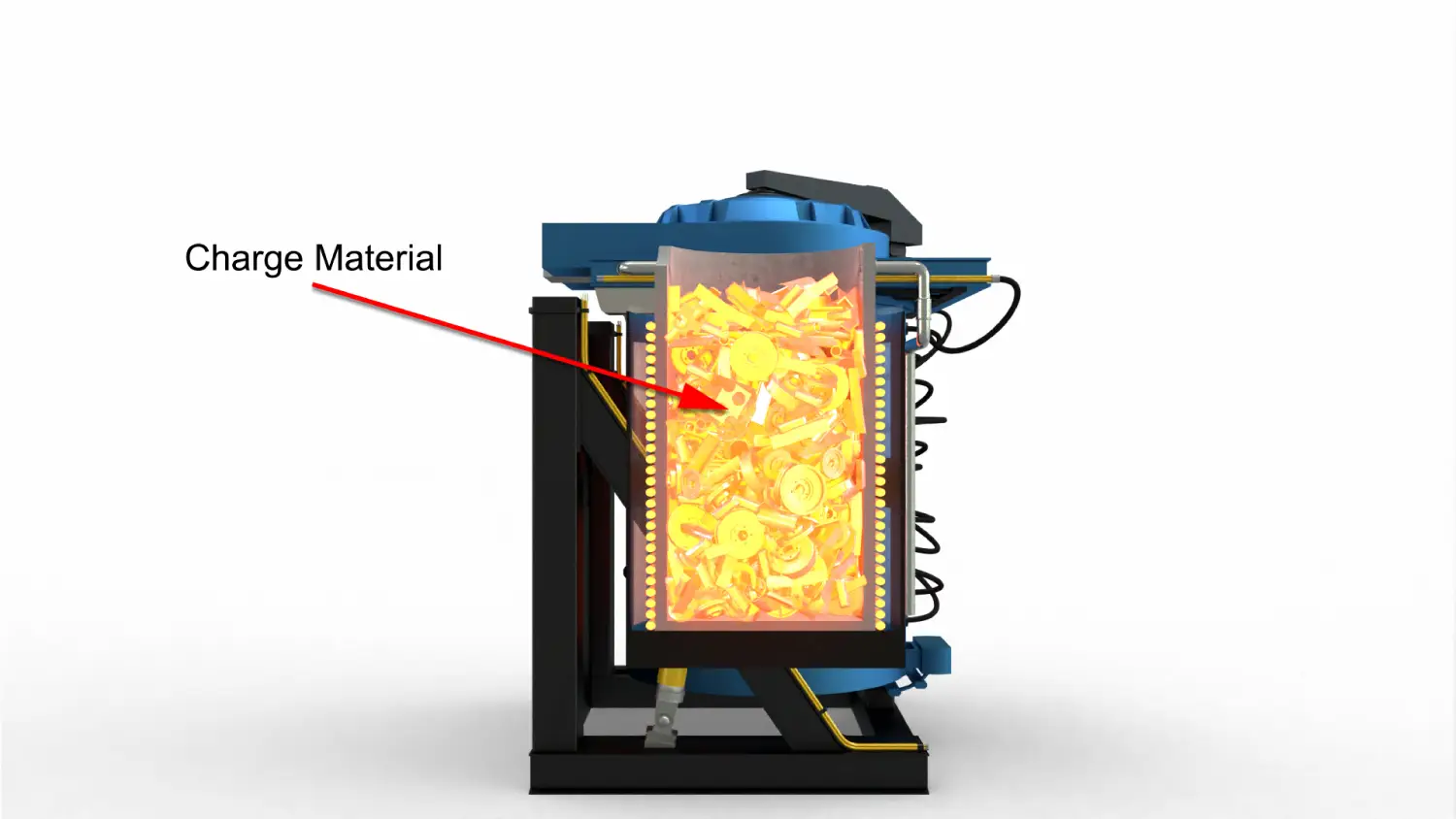

What is Induction Melting? Induction melting occurs when an electrically conductive object, usually referred to as charge material, is placed in an alternating electromagnetic field

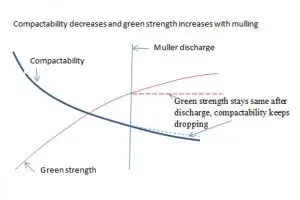

How to Control Compactability of Sand

Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and controlling the factors affecting it.

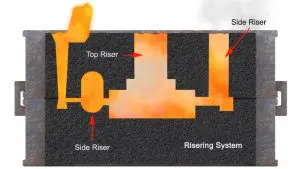

Investment Casting 101

Thousands of years ago duplicate metal structures were cast from an original sculpture by the lost-wax casting process. Investment casting is one of the oldest metal-forming