Course Description

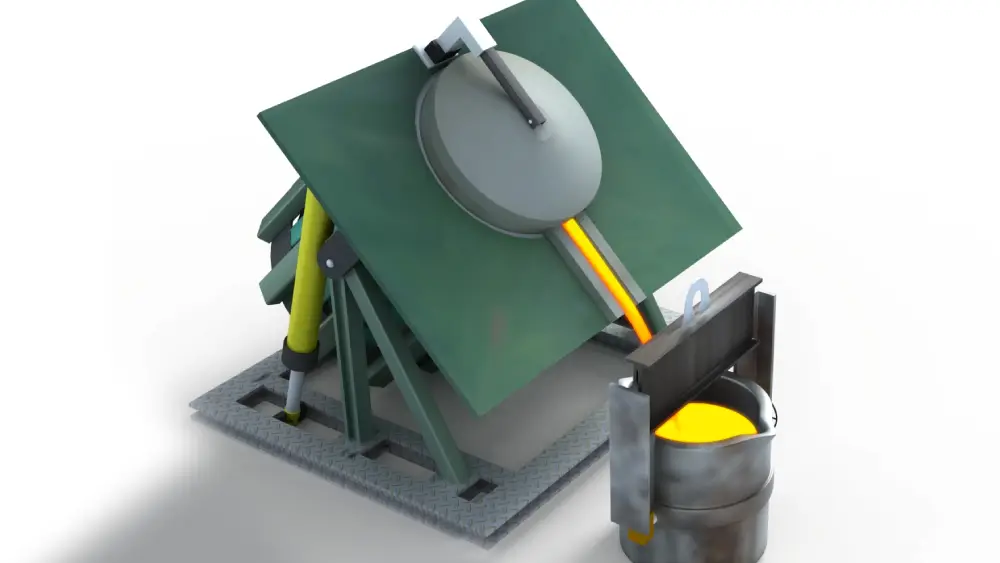

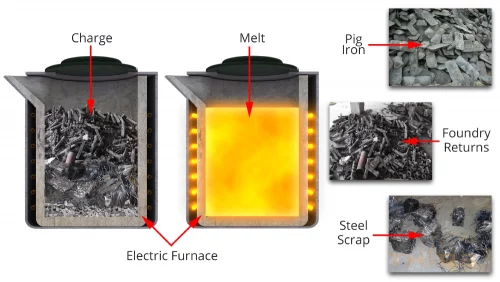

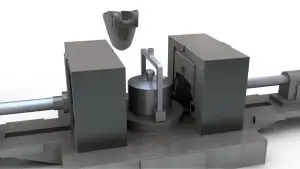

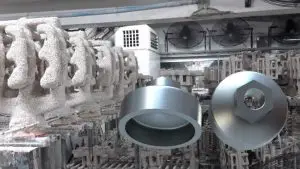

Castings: Charge Calculation for Cast Irons provides learners with the knowledge to more fully understand the materials, processes, and calculation steps involved in cast iron melting. Using THORS’ highly visual and interactive Lightning Learning format, this course succinctly summarizes a variety of steps in charge calculation procedures that are sometimes difficult to grasp. Charge material, melting furnaces, and chemistry analysis methods are just a few of the topics covered in this course. In addition, an example of a charge calculation is presented in a step-by-step manner to facilitate learning and comprehension.

Who will benefit from this Charge Calculation for Cast Irons course?

Quality, manufacturing, engineering, designing, purchasing, and sales.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Castings: Charge Calculation for Cast Irons

*upon successful completion

Related Posts

Must-read Monday: A mini-guide to basic foundry concepts

Every now and then we need to brush up on our knowledge. Let’s revisit some of our popular blog posts which are aimed to help

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also