Course Description

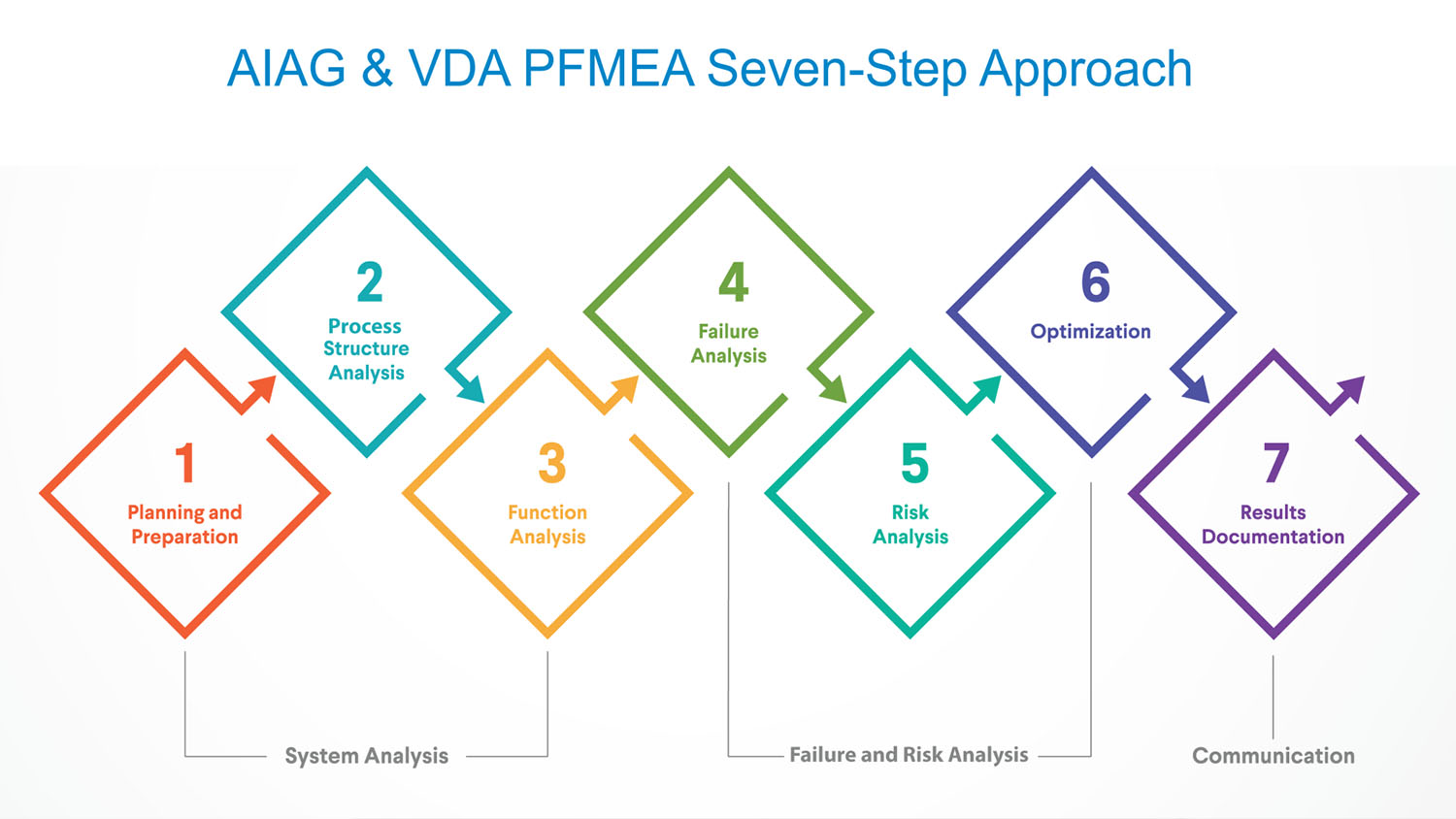

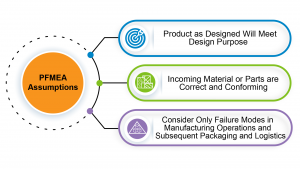

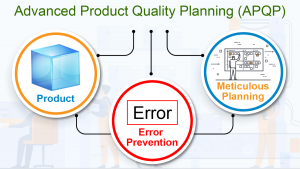

Risk analysis is an important step in the product development process to ensure safety. The THORS Process Failure Mode and Effects Analysis (PFMEA) AIAG & VDA course equips the learner with the knowledge needed to develop a PFMEA to optimize a process using the seven-step approach. This visually engaging and interactive course also explains the various FMEA types, PFMEA assumptions, PFMEA levels, and PFMEA maintenance along with a case study illustrated by a real-world scenario.

Who will benefit from this AIAG & VDA PFMEA course?

Marketing, Sales, Design, Engineering (Product and Process), Purchasing, Manufacturing, Quality, and Service functions at organizations that require an understanding of Process Failure Mode and Effects Analysis (PFMEA) from an AIAG & VDA perspective. Any learner who is required to understand and create an AIAG & VDA PFMEA.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Process Failure Mode and Effects Analysis (PFMEA) AIAG & VDA

*upon successful completion

Related Posts

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

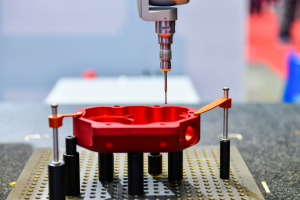

CMM Measurement Optimization: Best Practices for Accurate Results

Throughout the years, Coordinate Measuring Machines (CMMs) have earned a reputation for delivering accurate measurement results better than many other traditional metrologies. Implementing some best

A Differentiated Learning Approach: A Closer Look at THORS

In the wide landscape of learning methodologies, the pursuit of engaging and effective learning approaches has been ongoing. Among the myriad approaches, a differentiated learning