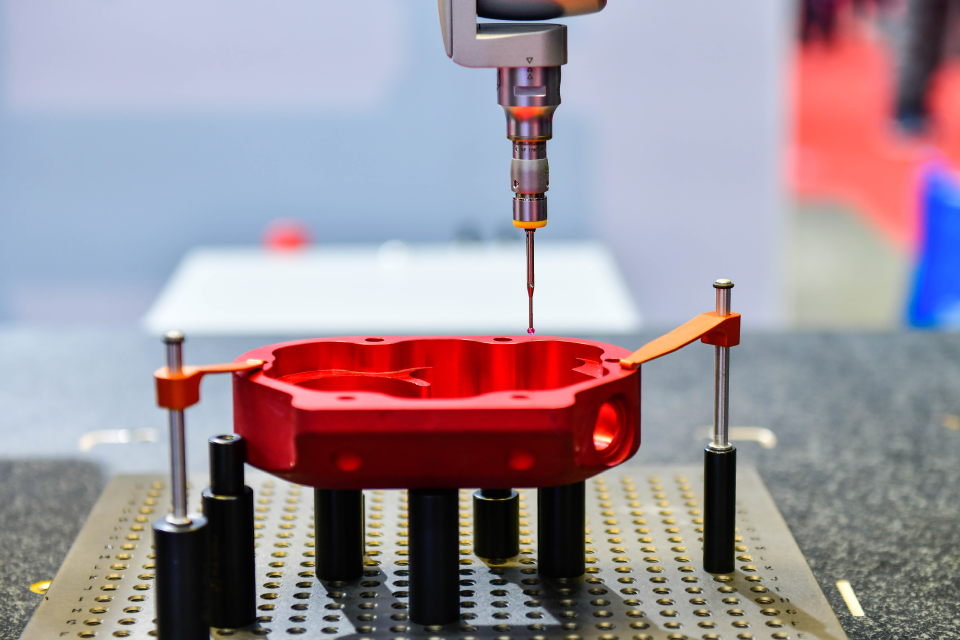

Throughout the years, Coordinate Measuring Machines (CMMs) have earned a reputation for delivering accurate measurement results better than many other traditional metrologies. Implementing some best practices for CMM measurement optimization will help reduce downtime and deliver reliable outputs.

Properly maintain the CMM

Cleanliness plays a significant role in maintaining the reliability needed for CMM measurement optimization. The stylus tip and the master sphere should always be kept spotless to avoid glitches in the measurement results. Although alignment, calibration, and probing processes might grab all the attention, simple procedures such as wiping the stylus tip clean, dusting off the master sphere, and keeping the equipment covered, should never be overlooked.

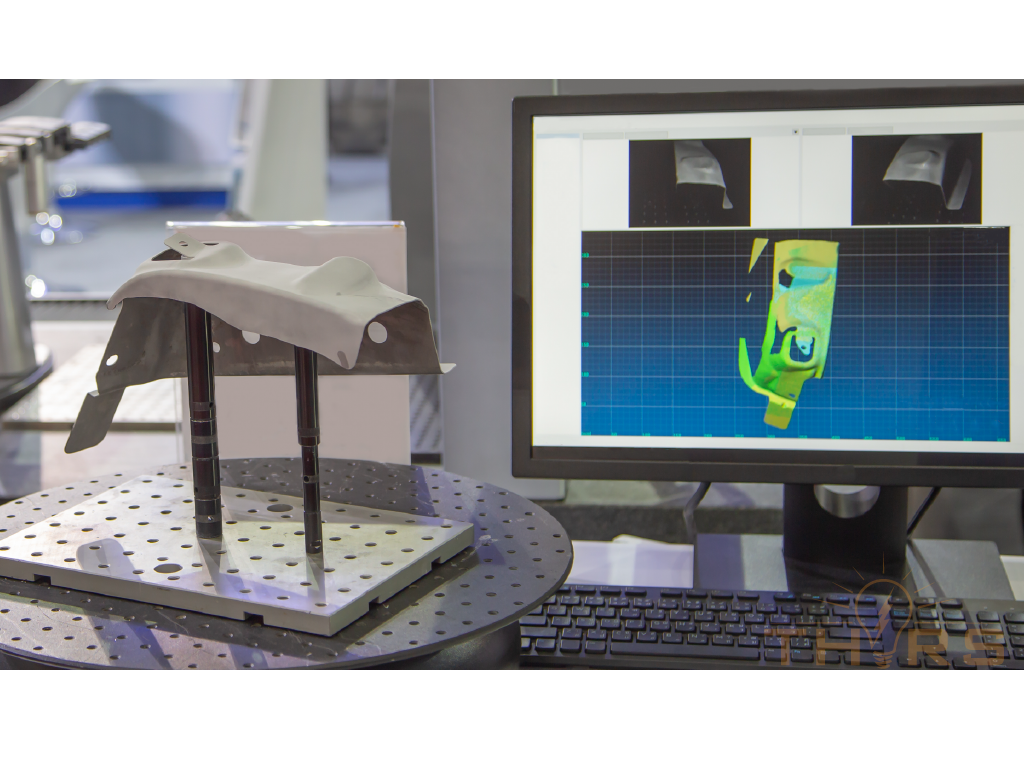

Use Computer-Aided Design (CAD) data to improve measurements

Collision risks to the stylus and the part during the measurement process can be avoided using Computer-Aided Design (CAD) data. Typically, a stylus runs the risk of collision when inappropriate force is applied. Collison may have a damaging effect on both the part and the stylus. CAD data can detect collisions prior to the measurement process.

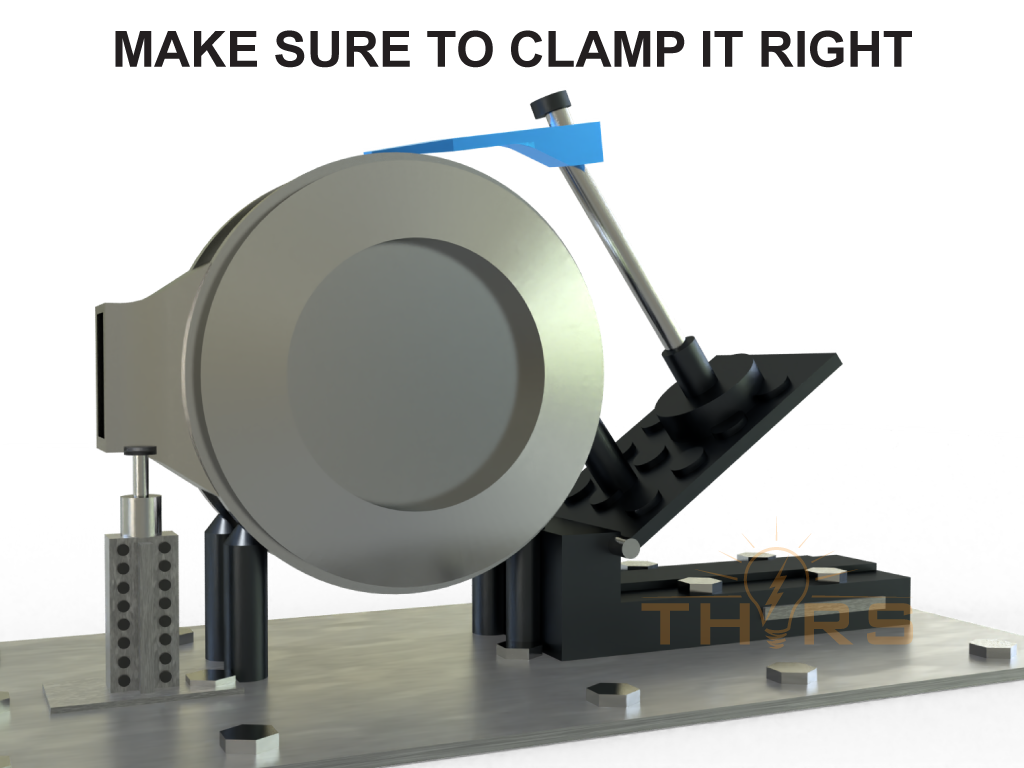

Develop a fixturing strategy to keep features accessible

Clamps can hinder accessibility to features when they interfere with the alignment points. Therefore, creating a fixturing strategy document with all the required data about the clamping sites, clamping force, and clamping sequence helps in running a reproducible program, maximizing productivity. Care should be taken to apply an appropriate clamping force which does not distort the part’s surface, while firmly holding the part in place.

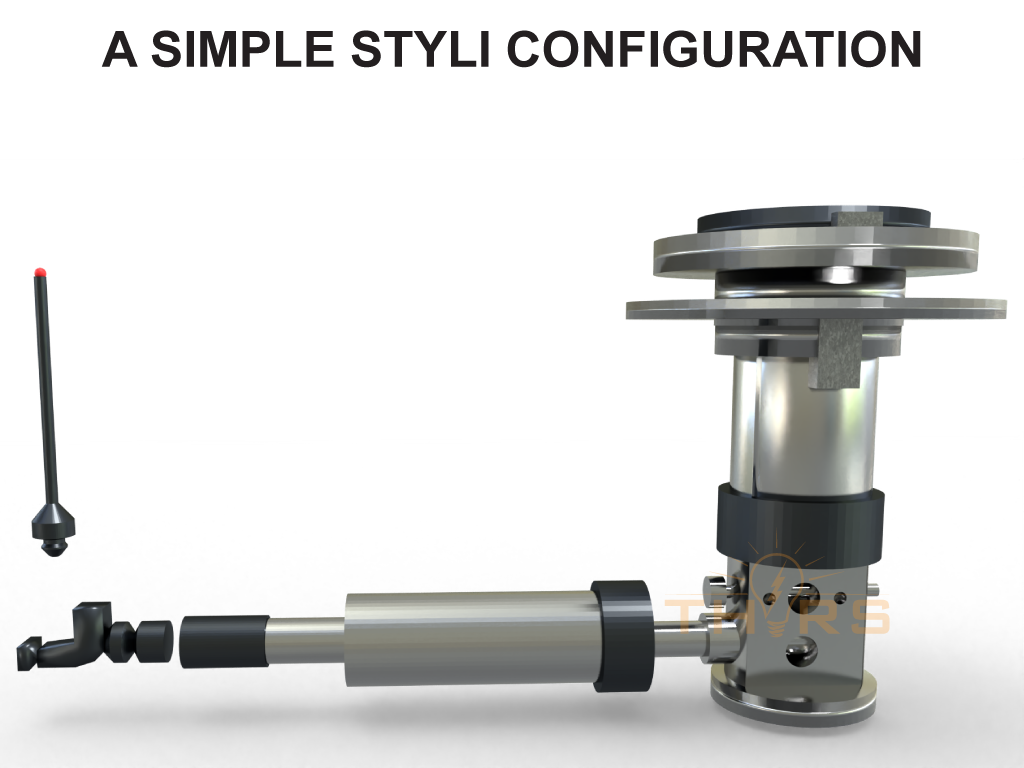

Determine an appropriate and simple stylus construction

In many circumstances, going with a simple stylus construction enhances measurement and keeps unnecessary complications away. Operators should ensure that the stylus in the configuration are stiff and sturdy. Generally, excessive joints, connecting elements, and extensions negatively impact measurement accuracy.

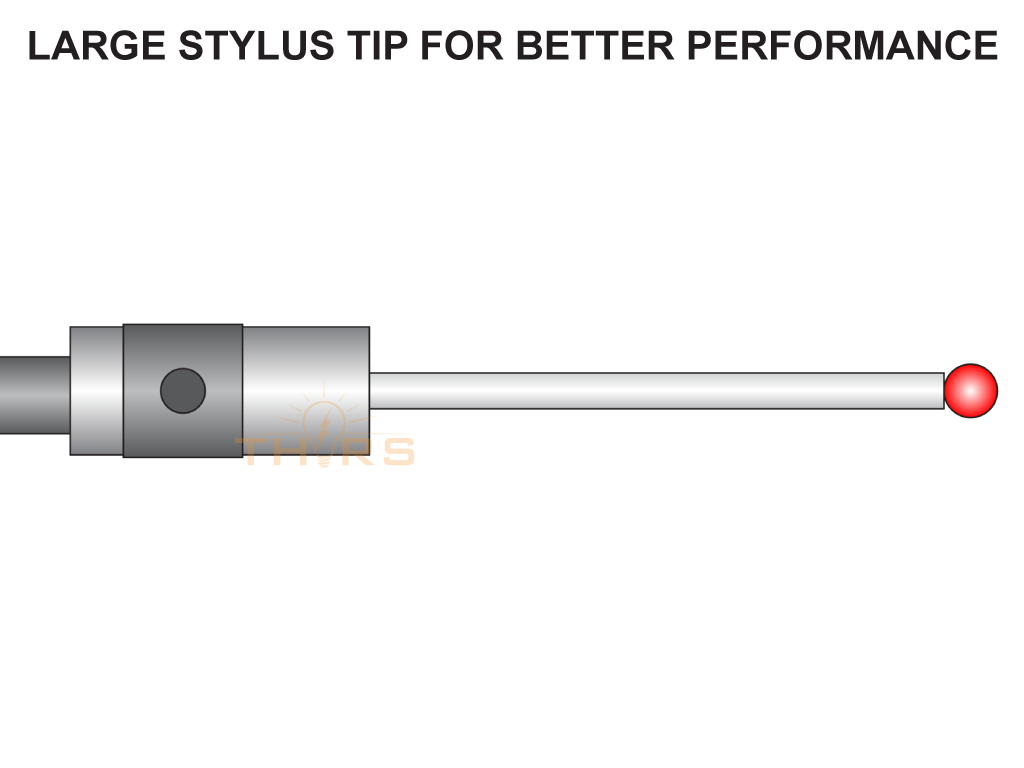

Choose a stylus tip with a greater diameter

When choosing the diameter of the stylus tip, it is better to opt for a greater diameter. Larger stylus tips are less likely to send false signals that are caused by the shaft hitting the part. Also, it is relatively easy to calibrate styli with large tips.

Train teams to use the CMM built-in features

CMMs are built with many capabilities and features to optimize measurement. A good knowledge of how to rightly access the features will enable using a CMM to the maximum advantage. A CMM operator should be trained to make sound judgements on selection of stylus, machine force, and strategies, to minimize the measurement uncertainty value and to help the machine perform at its highest caliber.

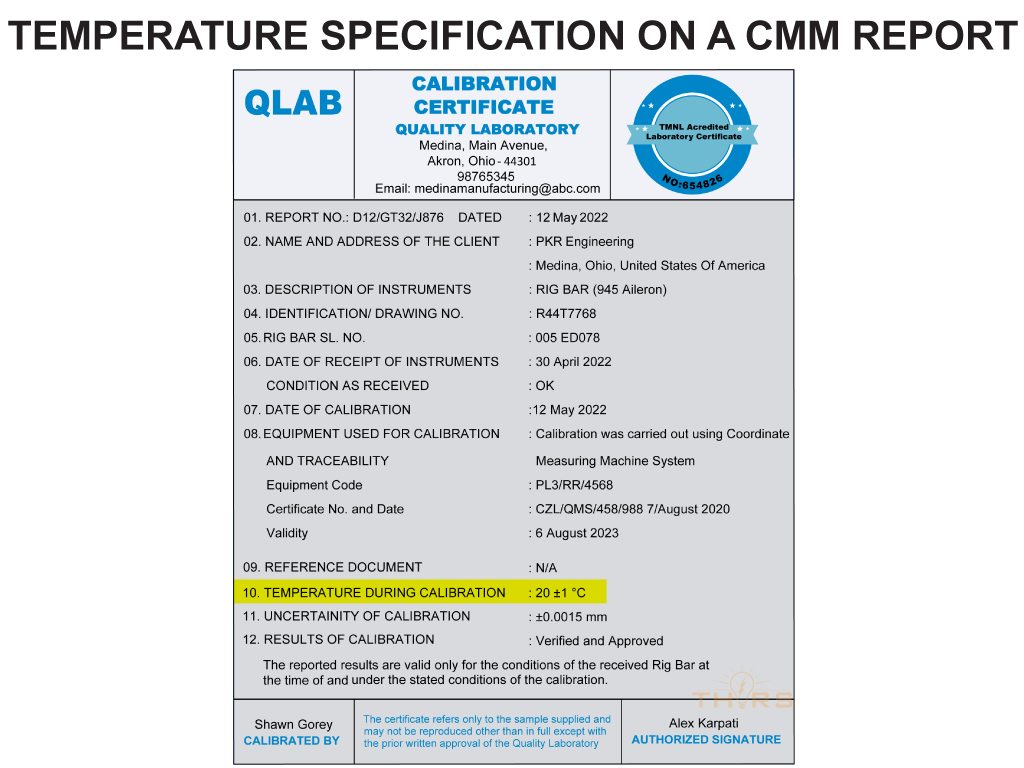

Maintain a constant temperature throughout the measurement process

Maintaining a constant temperature throughout the measurement process prevents measurement errors and helps maintain measurement repeatability. Compensating the data to the reference temperature of 20±1 °C (68±1 °F) is of paramount importance, since the temperature at which the part was measured by one machine will vary from the other, depending on place and time. The operator’s body heat can also potentially cause thermal expansion of the part. Therefore, to maintain temperature stability, the part should not be handled with bare hands.

Following these simple, yet effective, best practices for CMM measurement optimization will result in a CMM that becomes a trustworthy piece of equipment on the shop floor and in the laboratory.

Are you inspired to learn more about CMMs? The THORS course on Coordinate Measuring Machine (CMM) Basics would be the right start for you. The course is highly interactive, visually stunning, and engages the learners with creative, application-oriented questions to assess understanding.