Course Description

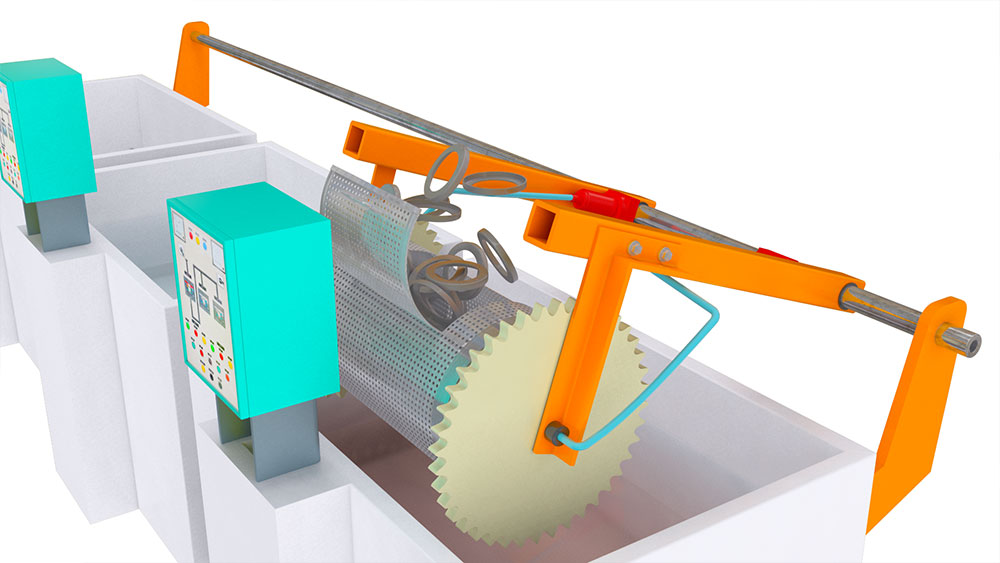

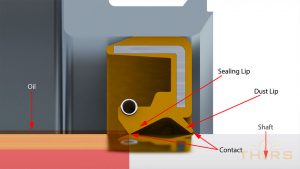

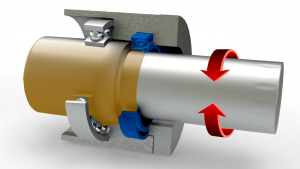

Oil Seal Fundamentals: Rotary Applications introduces learners to the overall concepts and terminology associated with oil seals used in rotary or radial applications. In addition, this course provides a variety of important tips and best-practice methods for the purchase, testing, and installation of oil seals. Using THORS’ 3D-animated and visually rich interactive format, the course also depicts the steps involved in properly manufacturing oil seals for modern applications. Whether the course user is new to oil seal industries, or is a seasoned veteran, there are practical learning moments contained in this course for everyone.

Who will benefit from this Rotary Oil Seals course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that require an understanding of rotary oil seals.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Oil Seal Fundamentals: Rotary Applications

*upon successful completion

Related Posts

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

How Can THORS Help Enhance Your College Education?

How Can THORS Help Enhance Your College Education? THORS Academy can help enhance your college education in a number of ways. Imagine being in a

The Versatility of Static Seals

The versatility of static seals is crucial in engineering as they ensure complete They play an essential role in appliances such as refrigerators and plumbing