Course Description

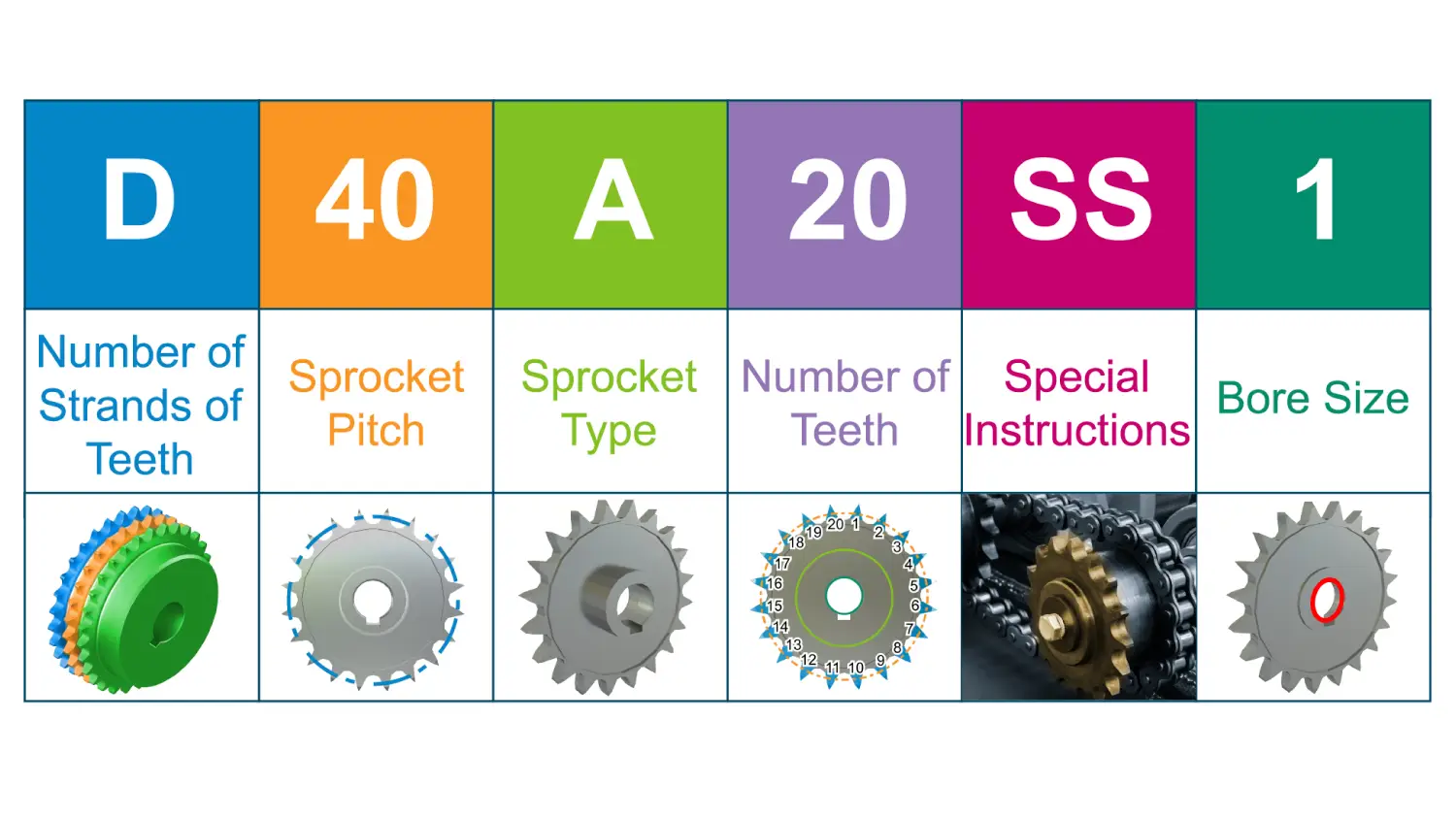

The THORS Sprocket Basics course explains the fundamentals of sprockets, which cover the terminology and nomenclature. The course offers an interactive learning experience that allows learners to gain an in-depth understanding of different types of sprockets based on various criteria, such as number of strands of teeth, function, detachment, hub design, shaft mounting, and materials. A visually engaging overview of the manufacturing methods, such as casting, machining, stamping, and powder metallurgy is also covered.

Who will benefit from this sprocket course?

Quality, manufacturing, engineering, designing, purchasing, and sales functions at organizations that require an understanding of sprockets.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Sprocket Basics

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

Boosting Employee Engagement in eLearning

Introduction In the realm of modern workplaces, boosting employee engagement in eLearning has become a pivotal factor in fostering productivity, job satisfaction, and overall organizational