The steel tubing industry is witnessing a remarkable transformation, driven by innovations in the field. The steel tubing industry has long been the backbone of various industries, from construction to automotive and beyond. As the demand for stronger, lighter, and more durable materials continues to grow, innovation in steel tubing production becomes crucial. Let’s review traditional methods and explore some of the exciting innovations revolutionizing the steel tubing manufacturing process.

The Traditional Methods

Before delving into innovations in steel tubing production, it’s essential to understand the conventional methods used in steel tubing production. Historically, steel tubing was primarily manufactured through two methods: seamless and welded.

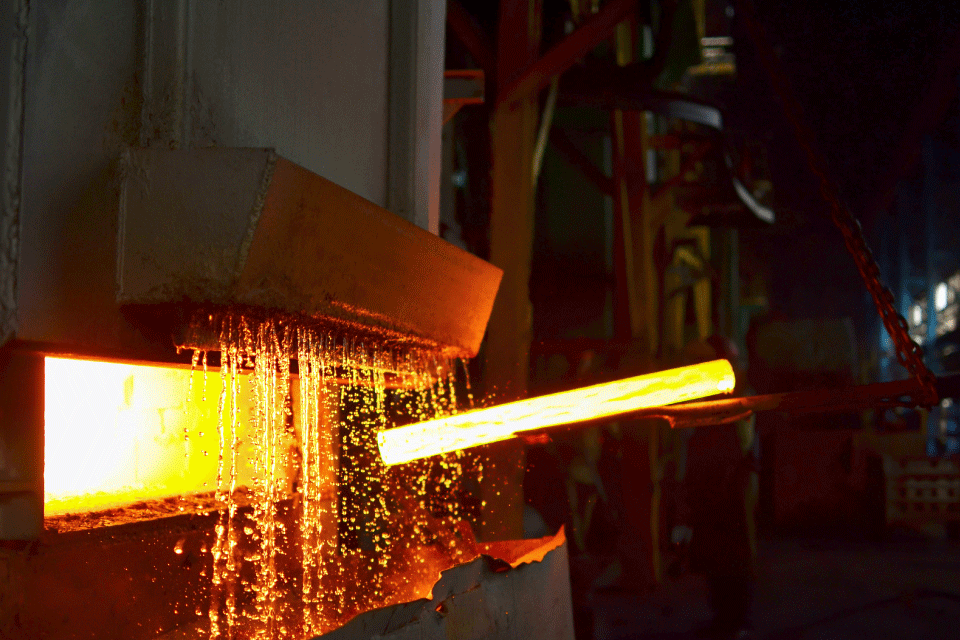

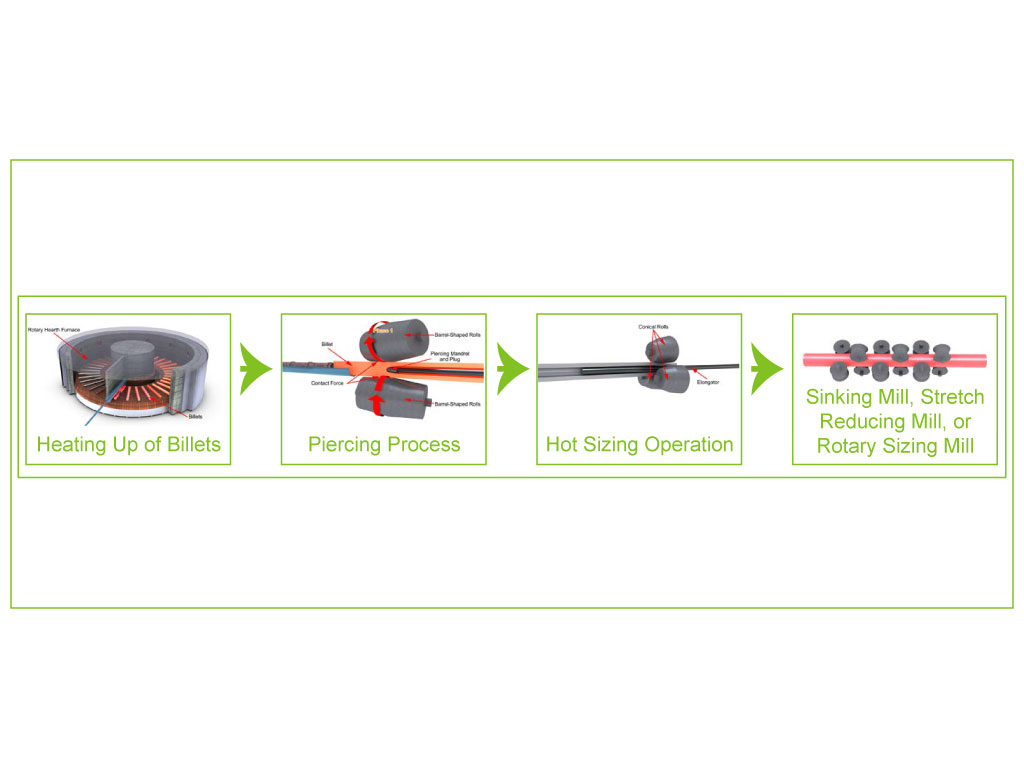

1. Seamless Production

This method involves piercing a solid steel billet to create a hollow tube, followed by elongating and reducing its diameter through a series of rolling and drawing processes. While seamless tubing is known for its excellent structural integrity, it is also expensive and time-consuming to produce.

2. Welded Production

In this method, flat steel strips are rolled into a tube shape and then welded along the seam. Welded tubing is more cost-effective but may have weaker structural integrity due to the welded seam.

To learn more about these two basic steel tubing production methods, register for our THORS Steel Tubing Production course today.

Innovations in Steel Tubing Production

Innovations in steel tubing production are experiencing a transformative period driven by new technologies and materials. The innovations with advanced metallurgy, introduction of composite materials, smart manufacturing processes, precise welding technologies, such as laser welding, and hybrid production methods are making steel tubing stronger, lighter, more precise, and environmentally-friendly.

1. Advanced Metallurgy

Recent advances in metallurgy have led to the development of steel alloys that are both lightweight and incredibly robust. These innovative alloys have opened up new possibilities in the design and production of steel tubing, making it possible to achieve better performance with less material. This not only reduces but also contributes to sustainability efforts by conserving resources.

2. Composite Materials

Combining steel with other materials such as carbon fiber or polymers can result in composites that offer the strength of steel with the lightweight properties of other materials. This innovation is particularly relevant in industries where weight reduction is critical, such as aerospace and automotive.

3. Smart Manufacturing

The integration of smart technologies, including sensors and data analytics, has improved the precision and efficiency of steel tubing production. Real-time monitoring of production processes allows for immediate adjustments, reducing defects, and improving overall quality. Predictive maintenance also minimizes downtime and ensures continuous production.

4. Laser Welding

Traditional welding methods often result in a noticeable seam in welded tubing. Laser welding, however, provides a nearly invisible seam. This innovation not only improves aesthetics but also enhances the structural integrity of welded tubing, making it more competitive with seamless tubing in certain applications.

5. Hybrid Production Methods

Combining different production methods, such as using 3D printing to create intricate internal structures and then applying traditional extrusion methods for the outer shell, can lead to the creation of highly customized and efficient steel tubing.

Conclusion

In conclusion, the steel tubing industry stands at the forefront of a new era, where traditional practices are being enhanced by ground-breaking innovations. These advancements in metallurgy, composite materials, smart manufacturing, laser welding, and hybrid production methods are not just incremental improvements. They represent a paradigm shift, offering solutions that are stronger, lighter, more precise, and environmentally sustainable. This evolution of innovation in steel tubing production is not merely a technical leap, it’s a step towards a more efficient and sustainable future for industries worldwide.

For those intrigued by the possibilities these innovations bring and eager to deepen their understanding of the steel tubing industry, we invite you to explore our comprehensive courses at THORS. Whether you’re a professional looking to stay ahead in your field or simply an enthusiast interested in the latest industrial advancements, our Steel Tubing Production course offers valuable insights into both traditional methods and cutting-edge technologies. Join us on this journey of discovery and be part of the new wave of industrial innovation.

Embrace the future of steel tubing with THORS – where learning meets the forefront of industry evolution. Enroll now and take your first step into a world where steel tubing shapes the backbone of our industries.