Course Description

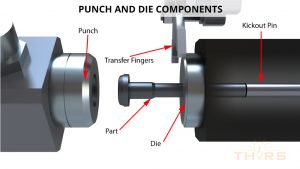

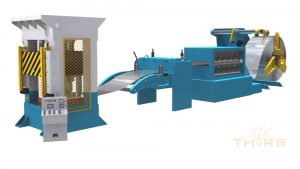

Cold Forming Fundamentals introduces learners to the equipment, processes, and general terminology used in cold forming industries. This course depicts the complex inner workings of cold forming processes with the aid of helpful GIFs and illustrations. A troubleshooting guide that covers both tooling and cold forming operations is also included in this course. This guide is a helpful tool to improve the quality and efficiency of cold forming operations. The material in this course is beneficial to both seasoned cold forming experts and learners new to the industry.

Who will benefit from this Cold Forming course?

Quality, manufacturing, engineering, designing, purchasing, and sales personnel.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cold Forming Fundamentals

*upon successful completion

Related Posts

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

A Differentiated Learning Approach: A Closer Look at THORS

In the wide landscape of learning methodologies, the pursuit of engaging and effective learning approaches has been ongoing. Among the myriad approaches, a differentiated learning

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools