Course Description

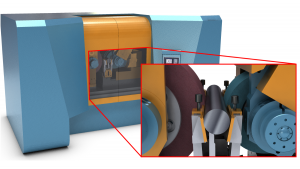

Discover the strategies that drive the choice of tools and processes for cylindrical grinding operations. The THORS Cylindrical Grinding Process Strategy course expounds the factors that play a crucial role in cylindrical grinding and guides the learner to apply the principles to develop a grinding strategy. This practical introduction, enriched with real-life examples, provides actionable strategies for better outcomes in cylindrical grinding.

Who will benefit from this Cylindrical Grinding Process Strategy course?

Design engineers, product developers, operations, quality, sales, and marketing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Cylindrical Grinding Process Strategy

*upon successful completion

Related Posts

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

6 common misconceptions about training

Training is one of the most important tools for growing in one’s chosen career. Participating in continued learning and career advancement training programs will ensure

How to Make Your Home Learning Environment Top Notch!

Since COVID shutdowns and the work from home revolution, there’s been a lot of discussion about making a home space conducive to working. But what