Course Description

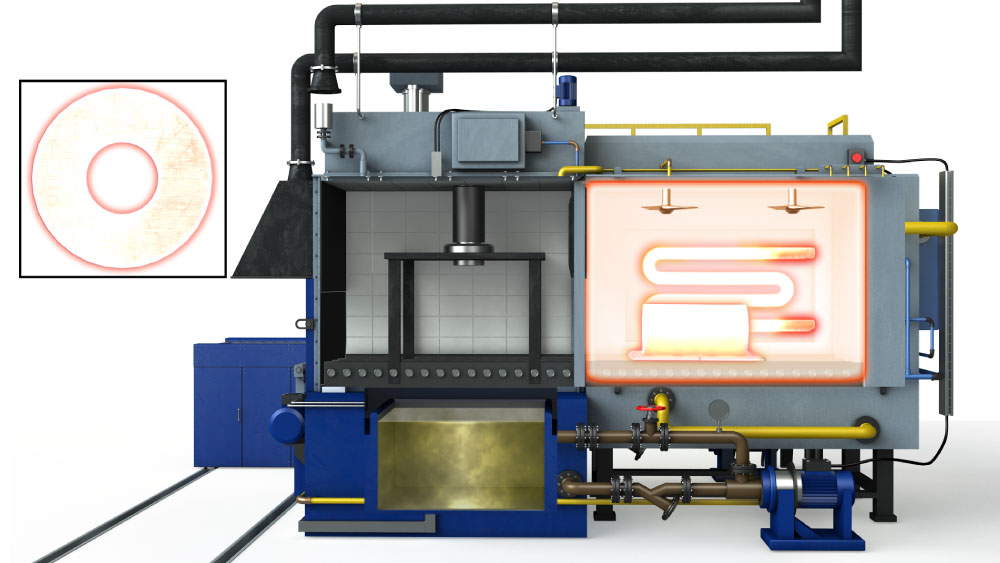

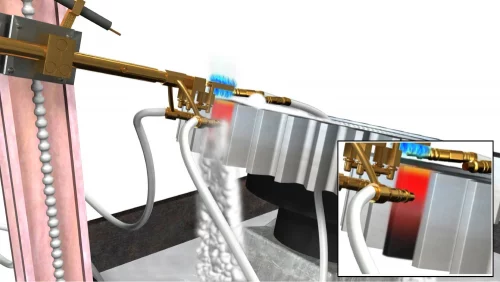

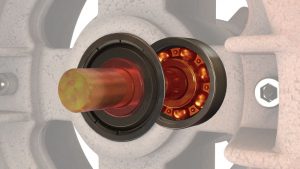

Heat Treating Processes and Equipment provides application-based knowledge for some of the most common heat treating procedures and equipment used in modern manufacturing. This course begins with introductory concepts and terminology associated with heat treating, and then delves further to highlight practical, application-based tips and approaches that are designed to improve the performance and efficiency of heat treating operators and specialists. The content provided in this course is presented in the typical THORS format: searchable, highly visual, and interactive-based learning. This course includes all of the material covered in the THORS Heat Treating Basics course.

Who will benefit from this Heat Treating Processes Equipment course?

Companies, individuals, or educational institutions that require knowledge about modern heat treating processes and the furnaces or equipment common to the industry.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Heat Treating Processes and Equipment

*upon successful completion

Related Posts

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.